Discuss about the Design and Installation of a Power Substation For a Mall.

An interrupted power supply to a large shopping mall complex is critical, especially, in ensuring continuity of business activities within and around the mall. Therefore, the document briefly outlines a work plan for a project to design, install and test the substation system of the mall. The substation transformer is supposed to step down 1250KVA power to a supply voltage of 480V. The main power utilities of the mall include lighting and power outlet. Importantly, however, critical design considerations will have to be followed. Top on the list include safety of occupants and the system itself. Notably, there have been other transformers installed by the company in the past. A review of their performance has been done as well and some slight modifications to ensure maximum safety and optimum performance were recommended. In this new project, which is just an extension of the past work, the recommendations made were put into consideration during the design, installation and testing of the new substation. Out of the many issues raised, safety was domineering. Hence, the project team leader decided to integrate some modern safety mechanisms during operation of the transformer. Certainly, therefore, the work plan hereinafter considers all the technical issues involved in designing, installing, terminating and testing the substation to comply with all relevant regulations.

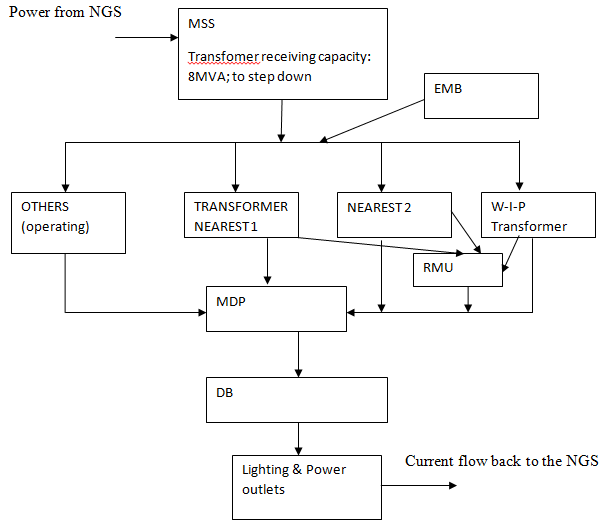

The whole power system is designed to cater for and surpass the power demands of a large shopping mall complex. It comprises of a main switching station (MSS) power capacity 8MVA with 13.8KV such that it supplies power to all the substations within the mall. The substation to be designed and installed is designated in the diagram as a work-in-progress (WIP). It is to be connected to the two nearest transformers via a ring main unit (RMU). The power from the mains transformer is supposed to be stepped down to 480V before being supplied to the distribution boards for lighting and power outlets. This is done via the main distribution panel (MDP). Now, the transformer to be installed, to cater for the mall extension, is supposed to have a capacity of 1250KVA power supplied from the mains transformer. Additionally, in case of power cuts, the system is integrated with an emergency main board (EMB) which is designed to automatically go online when power from the National Grid system (NGS) goes offline.

System Description

The following were identified as the issues to be considered during design of the substation:

- The environmental factors such as the location of the transformer, ambient temperature and humidity. Ambient temperature value will greatly assist the team to select the right type and capacity of the cooling system. Location is important as security issue is very critical. Additionally, the transformer will be designed to have the least effect on the environment (Ergon Energy, 2017).

- Safety factors: this will be observed through out the life cycle of the substation. Mechanisms to ensure safety during design, installation, testing, and termination shall be incorporated.

The transformer to be selected in this case is the shell-type. This type is normally designed to be used for large-scale application hence it will mostly be suitable in this case. While selecting the right transformer, the design parameters that will be derived include: Iron core area, number of turns both in the primary and secondary; the size of the conductor in terms in length and diameter; weight of the windings and currents on both sides. Now, design will also consider the transformer efficiency. Normally, in high voltage transformer huge power losses can be incurred if certain factors are not checked. Commonly, the two power losses in a transformer include: core and copper losses. For example, losses due to cable resistance will be overcome by optimizing the cabling sizes, although, it should not be too costly materially. So a kind of trade off will be arrived. Notably, as illustrated in the power diagram figure 1, the there will be two step down transformers; one in the mains supply and the other one in the substation to be installed. Depending on the location of the substation, although generally, the ambient temperature within and around the building will be almost uniform, however, a maximum value will be used to derive the cooling system. In the cooling system , mainly, we will derive the capacity and type of the cooling. Although air cooled are cheaper to install and maintain, however, they are often less efficient. However, on the other end, oil-cooled is better in terms of cooling efficiency but is more expensive to install and maintain. In the past work, air-cooled system was implemented although they have reportedly been growing less efficient, partly due to unpredictability of the blowing wind, which normally facilitates faster cooling. Besides, the air-fans used increased the operation costs as they also consume energy. Later, a decision was reached to have a mixed cooling system, a perfect compromise for the sake of operational performance. Hence both transformers will be integrated with a mixed cooling system such that the oil circulates around the core and an air-fan will be used to cool the hot oil afterwards.

As mentioned earlier, the two main losses in a transformer include: core and copper losses. Design will have to minimize these two losses.

Power Flow Diagram

Figure 1: Power flow diagram

Design Consideration

On receiving the transformer which will be in disassembled state, qualified inspectors will be on standby to ascertain that the transformer delivered conforms to the design requirements. Technical documents such as the bill of materials and invoice sheet will thoroughly be perused. Any thing about the transformer that may be suspect will have to be dealt before any installation works begins. Thereafter, installation works will follow the standard procedures as provided in the manual accompanying the components of the substation system. Importantly, the technical specification of the components such as transformer will be ascertained by an experienced professional engineer and the local legislations will be followed to the letter. Notably, proper installation is critical to ensure the system smoothly goes online ones commissioning is done. Among the critical issues to be observed include safety of the workers and the system components. In a nutshell, the following plan will be adopted (however, it is subject for revision):

Civil works to resume immediately allowing for faster healing of the basement and the sub-control rooms

The team will then be divided into groups and each group, under a team leader, will be assigned specific responsibilities. To facilitate proper planning and work scheduling, the team will be comprised of: Mechanical, Electrical and Civil groups. The mechanical group will be handling the installation of the transformer mechanical parts only. They will also be assisting with designing the layout of the substation. Principles of sound facility layout will be in handy. The transformer will then be sunk into the basement while the electrical group will be working on the cabling. Additionally, they will also ensure the entire circuit is done according to the circuit design. Laying of the cable will begin from the Mains supply, then connect it to the transformer primary side. On the other side of the transformer, secondary side will be connected to the Main Distribution board. Then lastly, cable will end at the distributions boards. Notably, the size of the cable will not be the same throughout the system. The cooling system comprising of the air –fans and oil tank will be assembled appropriately in their positions by the mechanical group. It should be noted that there will be daily work reports preparation to help with tracking of the project. The transformer will also be earthed appropriately.

Once the entire system is installed, testing of the substation will follow immediately. Now, there are a number of parameters to be observed during testing. The stepped down voltage from the transformer will be tested by reading the voltage output on the control board. Several readings will be taken after every hour. This will be done for the whole day to ensure stabilized system. The cooling system performance will also be tested and the values obtained will be compared with the one used when only the air-cooled system was installed. Safety and control mechanisms in the substation will critically be assessed by an experienced safety officer. Notably, the transformer will go online only when all the technical requirements are exhaustively addressed.

Conclusion

Therefore, this document briefly outlines the plan to be adopted in designing, installing and testing of the mentioned step down transformer. Some critical aspects have been considered during drafting of the document. Notably, however, some changes may be effected from time to time depending on the situation at hand. However, overly, the principles of best practices will have to be strictly followed; especially, safety of the people and the machine is very crucial. Notably, during commissioning, a representative from the energy ministry will be present to oversee the process. Some documents will be prepared in the process for future reference.

Reference

Ergon Energy.(2017). Substation Design Manual. Available at: https://www.ergon.com.au/__data/assets/pdf_file/0004/146839/NI000401R121-Subs-Design-Manual.pdf

Ulah, A. (2016).Calculations for Design Parameters of Transformer. Available at : https://engineerexperiences.com/design-calculations.html

ABB. (2004).Transformer Handbook. Available at: https://new.abb.com/docs/librariesprovider27/default-document-library/abb_transfo_handbk.pdf?sfvrsn=2

Pavlos S. (2006). .Methodology for the Optimum Design of Power Transformers Using Minimum Number of Input Parameters. Available at: https://users.ntua.gr/pgeorgil/Files/C52.pdf

Horizon Power. (2012). Standard: Substation Installation Technical Requirements. Available at: https://horizonpower.com.au/media/1387/hpc_9dj_23_0001_2012_sub.pdf

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2018). Design And Installation Of A Power Substation For A Mall. Retrieved from https://myassignmenthelp.com/free-samples/design-and-installation-of-a-power-substation-for-a-mall.

"Design And Installation Of A Power Substation For A Mall." My Assignment Help, 2018, https://myassignmenthelp.com/free-samples/design-and-installation-of-a-power-substation-for-a-mall.

My Assignment Help (2018) Design And Installation Of A Power Substation For A Mall [Online]. Available from: https://myassignmenthelp.com/free-samples/design-and-installation-of-a-power-substation-for-a-mall

[Accessed 21 December 2025].

My Assignment Help. 'Design And Installation Of A Power Substation For A Mall' (My Assignment Help, 2018) <https://myassignmenthelp.com/free-samples/design-and-installation-of-a-power-substation-for-a-mall> accessed 21 December 2025.

My Assignment Help. Design And Installation Of A Power Substation For A Mall [Internet]. My Assignment Help. 2018 [cited 21 December 2025]. Available from: https://myassignmenthelp.com/free-samples/design-and-installation-of-a-power-substation-for-a-mall.