The Business of YAS

Discuss about the Business Excellence for Yokogawa Electric Asia Pre LTD.

Yokogawa Electric Asia Pre LTD was incorporated in Singapore in the year 1974. Over the past 38 years, the organization has grown to the extent of becoming a global engineering based productivity center (Yokogawa Electric Corporation, 2016). Currently, the business accounts for approximately 75% of the enterprise’s supply of distributed control system all over the world (OKI to Take over Yokogawa Electric Site in Ome, 2015). The company is engaged in activities including industry and engineering support. Through its operations, Yokogawa has a vision of becoming the world’s best manufacturer and suppliers of control systems in 2015. Hence, the company’s mission is to provide outstanding services, contribute significantly to advancing the society, and innovate the spirits of its people.

Yokogawa works in an active environment. As stated in the report summary, the managing director is proud of employees, meaning that the latter is working tirelessly to ensure that the company excels. The commitment of employees can only be achieved in a positive working environment. To affirm this, the manager went further to state that the business has a culture and core values that responds amicably to the requirements of stakeholders such as shareholders, employees, the supply chain partners, customers and the community. This work culture is a sign of value and respect to stakeholders hence, ethically sensitive. Notably, the economy uncertainty is ongoing, a situation that has made the operating environment more complicated. The competitiveness of the industry has resulted into the incorporation of quality and safety of products, reliability in delivery and innovation into the workplace.

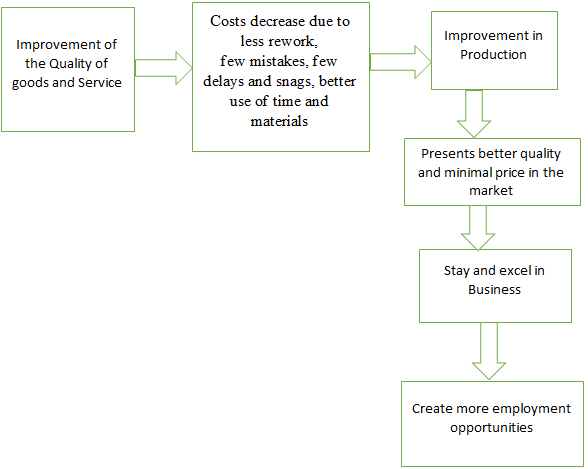

Deming chain reaction model was developed in the year 1986 by Deming, who proposed the chain model to explain the relationship that exists between quality, cost, productivity and sustainability (Wayhan, Khumawala, and Balderson, 2010). In his tool, Dewing stated that improvement in production activities reduces costs because the mistake is minimized hence, no rework. Furthermore, a general improvement in productivity and cost results to a significant enhancement in market share. The increase in market share improves a company’s position in the market. This model is summarized in figure 1 bellow.

Fig 1.

From the interpretation, if the above is the mode, it is evident that it was important for YAS to obtain the Singapore Quality Award (SQA) because YAS is focusing majorly on sustainability. Towards this focus, the company improves Deming chain reaction models key pillars such as quality, cost innovation, job creation and being competitive.

The Business Environment

Plan-Do-Check-Act (PDCA) is a four method management technique applied in business to control and improve product and operation processes. While designing this tool, Deming believed that a primary production quality source is an established defined process. Such procedures must be transparent and repetitive (Roesser, 2007). This model comprises of four phases; plan, do, check and finally act. The tool is used to encourage business operators to be more methodical in their approaches to challenges through the implementation of solutions. To get the highest possible settlement, steps bellow are followed;

As the name suggests, this move entails planning, which begins with the identification of exact issue affecting an organization. Identification of the problem requires the use of other strategic tools such as for cause and effect diagram and drill down. These tools help in getting to the root of the cause of the problem. After identifying the issue, the poses is mapped at the origin of the challenge. To wind up, helpful information is drawn to assist in sketching the generation of the solution.

This action begins with the generation of alternatives, followed by a selection of the best. This activity may be facilitated by appropriate techniques such as impact analysis. After the most suitable solution is obtained, the driving solution is implemented on a tiny scale basis. Similarly, other suitable trial designs can be used.

In this stage, the effectiveness of the pilot solution is measured, while areas and ways of adjusting the design are collected. Depending on the efficiency of the best option, the number of improvements identified, and the length of the entire initiative, this step can be repeated for two or more times. Once the design is satisfactory, the process is carried to the next phase.

This stage entails acting by putting the most amicable solution into full practice. However, the use of the tool does not stop at this juncture.

Plan-do-check-act is suitability for use by any company seeking to improve quality because; the device compels the management, making it accountable for any outcome of the program. Besides, it offers a recommendable method for external validation. Also, choosing the most appropriate solution out of the entire solution list, and checking its affectivity before acting ensures that all mistakes are corrected.

Deming prize has imposed a substantial effect directly and indirectly on quality development and management in Japan. Applicant companies and division of businesses sought beneath new methods to quality control according to the requirements of their businesses’ environments. About Deming prize, the organizations developed effective methods of managing quality, established the design for implementation and applied the techniques. According to Breja et al. (2016), Deming prize does not need companies to conform to the model. Rather, the company should possess the following qualities before applying for the Deming Prize; valuing partners, managing with Agility, understanding the business situation, establish own themes, transform and the ability to improve all over the organization (SQA) (Garza-Reyes et al., 2016).

Deming Chain Reaction

As noted earlier, PDCA is a four method management technique, used to control and manage the improvement of product and operation processes. Yas uses the PDCA in the performance improvement system. In such occasions, the company gathers brainstorm to formulate development strategies. To this effect, the business set up roadmaps in various enterprises within the group, representing the first and second step of the PDCA respectively. After that, the organization set new targets for global revenue generation. Alongside, innovations and the capital needed for the expansion are set then translated into the business’ QDCF, and results reported back to the manager on a monthly basis. Finally, improvement initiatives and performance gaps are monitored before the final implementation, just the same way dictated by the PDCA tool.

The Business Excellence Framework offers a set of management standards for company excellence. The framework illustrates the cause and impact relationships between the performance drivers and the outcome obtained. Characteristics of Excellence shows primary attributes of high performing enterprises; are enclosed throughout the critical framework drivers. The Organizational sets the context for the way the company operates. It also serves as a guide for how the structure is put into practice. In the framework, there are seven criteria applied to assess a company. The first criterion is leadership, which sets the direction for the enterprise and controls the mindset of excellence.

Customers are the second approach, positioned after administration to show the focus on consumer centricity. As the third criterion, the strategy is developed depending on the understanding of the requirements of the internal and external stakeholder. This knowledge guides the development of the ability of People and Process to obtain desired Results; representing the fourth, fifth and sixth criterions in that order. The seventh rule is knowledge. Knowledge is part of feedback of innovation and learning. All these supports the decision-making process hence, driving improvements.

The key to excelling in SPRING Singapore Business Excellence journey lies in the learning and innovation of the organization. Every firm has to possess unique qualities to exist and thrive in the market. These unique traits regarding skills are summarized under innovation capabilities. Innovative capabilities represent ways in which a company harnesses innovation to design new goods and services, and how production activities relate to delivery system. Change is implemented by primary stakeholders such as shareholders and employees. Regarding design, employees at the manufacturer use packaging techniques that appeal most to the consumer. The design is effected regarding the shape and packaging materials.

Plan-Do-Check-Act (PDCA)

On the other hand, process management entails means in which products are manufactured and delivered to various consumers. Process management is the process of encamping activities of monitoring and planning the business performance. It is the use of skills, tools, methods, and knowledge to define, measure, visualize, report, control and enhance processes while aiming at meeting the needs of customers. Therefore, process management initiates the adoption of approaches used to develop, improve and implement the effectiveness of the directorate system.

As stated earlier, innovation capabilities entail acquisition of useful traits. Organizations must use technology alongside highly skilled employees to come up with the most appealing designs. Apparently, a company may have qualified workers, but their products may still fail to appeal to the market. This scenario can be evident due to lack of commitment by employees. Therefore, the second requirement is commitment. The engagement of employees is boosted by a conducive working environment, possessing healthy relationship between various stakeholders, initiated by a good communication plan meaning that information is also a vital requirement. Just like innovation capability, process management is a direct way of engaging employees. Therefore, their commitment is required for efficient process control. At the same time, employees involved in product management should be skilled enough being that this process is more professional. There should also have been a good communication between them to enhance working relationship between them. To sum up, requirements of innovation capabilities and process management are technology, information, a good communication plan and commitment of employees.

According to items discussed in 5.1 and 5.2, and in response to operations rules, organizations equips innovation in many ways. Some of these ways are e designing products and services in line with technology. This harness is also applied in the production and delivery system. It may also require information gathering from relevant stakeholders such as employees. In conjunction with process management, there are need mitigating emergencies; technology can be applied to enhance innovation, and modification of existing products, therefore relating directly to the system used by YAS. As evident in the regular items, incorporated innovation, and technology as it majors on sustainability by ensuring product quality.

Reference

Breja, S. K., Banwet, D. K., & Iyer, K. C. (2016). Towards sustainable excellence: strategic analysis of Deming Prize winning companies. TQM Journal, 28(3), 390-410. doi:10.1108/TQM-09-2012-0070

Garza-Reyes, J. A., Visnevskis, F., Kumar, V., & Antony, J. (2015). A review and comparative analysis of the Russian Federation Government Quality Award. Measuring Business Excellence, 19(4), 1-16. Doi: 10.1108/MBE-08-2014-0028

OKI to Take over Yokogawa Electric Site in Ome. (2015). Printed Circuit Design & Fab: Circuits Assembly, 32(5), 8.

Roesser, K. (2007). Decreasing the risk of chemotherapy errors through a failure modes and effects analysis (FMEA) and a focus PDCA (plan, do, check, and act) quality improvement model. Oncology Nursing Forum, 34(2), 510.

Wayhan, V. B., Khumawala, B. M., & Balderson, E. L. (2010). Empirical enhancements to Deming's chain reaction model. Total Quality Management & Business Excellence, 21(7), 779-789. doi:10.1080/14783363.2010.483105

Yokogawa Electric Corporation. (2016). Yokogawa Electric Corporation MarketLine Company Profile, 1-26

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2018). Business Excellence For Yokogawa Electric Asia Pre LTD. Retrieved from https://myassignmenthelp.com/free-samples/business-excellence-yokogawa-electric-asia-pre-ltd.

"Business Excellence For Yokogawa Electric Asia Pre LTD." My Assignment Help, 2018, https://myassignmenthelp.com/free-samples/business-excellence-yokogawa-electric-asia-pre-ltd.

My Assignment Help (2018) Business Excellence For Yokogawa Electric Asia Pre LTD [Online]. Available from: https://myassignmenthelp.com/free-samples/business-excellence-yokogawa-electric-asia-pre-ltd

[Accessed 31 May 2025].

My Assignment Help. 'Business Excellence For Yokogawa Electric Asia Pre LTD' (My Assignment Help, 2018) <https://myassignmenthelp.com/free-samples/business-excellence-yokogawa-electric-asia-pre-ltd> accessed 31 May 2025.

My Assignment Help. Business Excellence For Yokogawa Electric Asia Pre LTD [Internet]. My Assignment Help. 2018 [cited 31 May 2025]. Available from: https://myassignmenthelp.com/free-samples/business-excellence-yokogawa-electric-asia-pre-ltd.