Nike ships products directly to customers

Discuss about the Logistic Management and Strategy of Nike.

Direct to consumer advertising or marketing is a popular form of marketing endorsement that is aimed in the direction of the end patient rather than healthcare professionals. Nike’s distribution system was traditional system in which the customers used to get their products through the vendors. However, after the introduction of social media everything changes. The biggest change that social media brought with itself is the change in business concepts (Distelhorst et al. 2016). Most of the business organizations started to use social media as their promotional tool. However, things changes when some companies started online sites from when customers can buy products without walking into shops. Nike noticed this trend in business and saw that some organizations gained tremendous success through this process. Aamazon is the biggest example of that. After that the management of Nike decided to hop into e-commerce and introduced their online shopping site named as Nike.com (Ross 2013). In a little time the organization realized that their decision was not wrong as they started to gain more attention and from customers and their profit started to go up in an unexpected manner. That was the time when the management of the organization decided to enhance this process in order to strengthen their market hold.

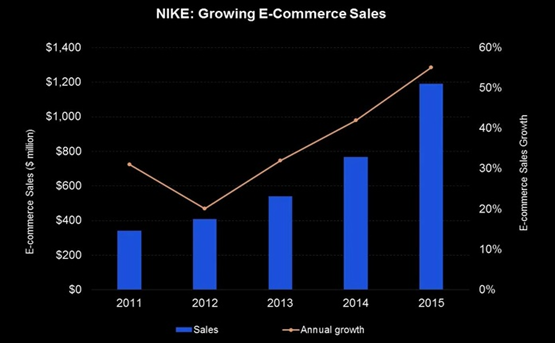

Nike has started to use Direct to Consumer (DTC) channels in order to improve their brand statement and to push sales of premium products. Through DTC, Nike is able to have better flexibility over pricing, inventory and commodities decisions. The management of the organization expected that, as DTC channels sales are periphery accretive, it will help the association to reach its target of a 0.4-0.6 percentage point growth in its gross margin each year through fiscal 2020 (Hoejmose et al. 2013). From the figure 1, it can be said that Nike was able to meet its targets till date by using DTC channels. However, there were some other major reasons that allowed Nike to implement such as channel in their supply chain.

(Source: Schaltegger and Burritt 2014)

Marketing department of Nike could understand that web services will provide greater options to Nike which will give them a competitive edge over its customers and will provide a better customer services. Besides, the organization also understood that being a sports good selling company, they must have a digital initiative which will serve as an important source of customer data helping them to develop new products targeted as specific consumer segments (Buddress 2013). Besides, Nike also understood that social media is a necessary tool for engaging with the customer that will help its marketing team to provide better customized and personalized options. Product customization by NiKEiD and improvements it it’s SNKRS app was introduced in February 2015. These options allows Nike to stay ahead of new footwear brands such as Skechers that reported a sales growth of over 30% in the year of 2015 (Kozlenkova 2015).

Reasons to start satellite centers

More importantly, e-commerce business has emerged as a profitable one and a margin enhancer for all the business organizations. It is also responsible for attracting more customers towards a brand. For example, if a customer is looking for a sports shoe and walks into a retailer shop, the retailers will obviously prioritize what sells (Pullman and Collins 2013). If that customer is not sure about a pair of shoes from Nike, but they can close the same deal by buying a Reebok, retailers will sell the Reebok shoes to them without thinking twice. This situation will not take place in case of e-commerce selling which is direct to customer process. Besides, at its initial stage, Nike.com helped the organization to acquire more sale than any other competitor in the market there it came out to be a profitable venture for the organization. According to Qrunfleh and Tarafdar (2014), direct to consumer sales of Nike grew by 15% and reached to $3.7 billion in the last quarter of 2015 which was supported by a 10% increase in same-store sale and high growth in their e-commerce channel.

As mentioned by Shi and Yu (2013), rise of upgraded mobile technologies, technologies related to social and cloud processes, customer expectations continue to rise. Customers are nowadays looking for a more seamless experience. In the industry from where Nike belongs, customer experience is a new battlefield. It is considered as a major competitive advantage that attracts and keeps customers. Direct to consumer sales process through online sites allows business organizations to envision how the customer journey should take place. As a result, marketing team of that company can implement the tactics necessary to make that vision a reality (Sajjad et al. 2015). Nike management considered these points and then decided to open direct to consumer channels.

Another major reason behind Nike’s decision to open direct to consumer is the facility of DTC that allows an organization to collect customer behaviour data. Direct to consumer channels are a big chance for companies to develop the lifetime value of consumers because those companies can garner knowledge about their consumers and tailor personalized sopping experiences them. However, it is also true that data cannot provide a complete knowledge on the current customer behaviour; therefore, an organization should also use traditional channels to keep a steady communication with the customers (Lemke and Petersen 2013). Nike’s decision to implement direct to consumer channel was also influenced by the introduction of several newly launched organizations that are having unique marketing style. The organization decided to reach to its customers more precisely and that is why they decided to hop in e-commerce business.

In spite of having traditional centralized model, Nike is planning to have satellite centres. In this new distribution model inventory will be managed through both the central warehouse and the satellites. This process is mostly used in European logistics organizations for each market channel (Tachizawa and Wong 2015). However, this needs central coordination of stocking policies for the individual satellites. The management of Nike realized that full supply chain visibility is highly important for the organization where central warehouse will be able to view stock levels, original demand and sales forecast for each satellite facility. This type of visibility will help Nike to continuously optimize order delivery. This can be done either by direct deliveries to customers from the central warehouse or by deliveries from satellite facilities. It will also help Nike to optimise its inventory continuously through location or relocation of products and stock among central warehouse and local satellites. As mentioned by Xu et al. (2014), this type of visibility will help Nike to facilitate cross-docking and combine-in-transit activities at all warehouse locations. It will also help to strengthen the tracking and tracing of goods and orders across the total supply chain. It will allow Nike management to easily perform and maintain control over the flow of goods.

Virtual warehousing is a famous model of supply chain that creates full visibility of inventory at all stocking points within a specific area. In this way, an organization can fulfil any kind of order from anywhere in the network without considering where the goods are stored. However, some organizations still prefer flexible warehouse solutions and Nike is one of them. Nike decided to follow the model after Wal-Mart gained extreme success with it. Wal-Mart was the first organization that introduced companywide use of Universal Product Code bar codes (Ageron et al. 2012). It helps to collect and analyze store level information. At Wal-Mart, their retail link stays connected with the analysts who forecast supplier stress to supplier network that shows real-time sales data from cash registers and to the distribution centres of Wal-Mart. In this supply chain, suppliers and manufactures harmonize their demand projections under a concerted planning, forecasting and replacement scheme. Each of these schemes in the chain remains connected through technology that contains central database, store-level point-of-sale systems and a satellite network. This type of supply chain is another major reason of Wal-Mart’s immense success. All the information that is collected are shared with the partners.

In addition, Wal-Mart also networked its distributors via computers. The organization entered into cooperation with P&G in order to maintain the inventory in its stores which helped them to develop an automated re-ordering system. This automated re-ordering system created a connection among all the computers of P&G factory though satellite communication system. Then P&G delivered the item either to Wal-Mart allocation centre or unswervingly to the store. Nike management noticed this operational advantages of using satellites in supply chain management and that is why the management decided to use satellite centres in their supply chain management.

According to Cruz (2013), supply chain cost of online accessories retailing are twice the distribution costs of traditional systems. Traditional distribution channels are much more efficient as customers do the most labour-intensive work for the retailer by picking the order from the store and transporting products. Cost of such activities are nearly 10% if the consumer price. Besides, organization have to pay recruit well-trained and qualified workers to do this tasks without any type of error.

After analyzing the advantages that Wal-Mart gained through their satellites, Nike was influenced to use the same in their supply chain management. Besides, supply chain satellite offers objective insights into a company’s logistics procurement strategy that in turn supports decision making related to logistics outsourcing. Supply chain satellite is known as a joint venture of Supply chain media, Nyenrode University, DSV and Districon. This supply chain model generally uses a four quadrant model to envisage a company’s location within the strategic landscape (Porteous and Rammohan 2013). The first step is used to scrutinize the current situation which is an exercise of self-reflection that helps to decide which types of logistic systems an organization wants to use. That is why, in spite of having a centralized supply chain system, Nike decided to open a satellite centre of their own.

The main purposes of packaging are protection of product, attractiveness of product, co-operation with channel and segmentation. It is known as a technology for protecting products for distribution, storage, sale and use. According to (), packaging is also described as a coordinated system of preparing goods for transport warehousing sale and use. On the other hand, labelling is known as a written or graphic communication on the package or on a disconnected but associated label. Both the systems have some advantages for which they are an important operational part of distribution channel.

Packaging provides different advantages to different types of segments. Some advantages of packaging are provided below,

Advantage to manufacturers: Packaging helps the manufactures of Nike to keep the product safe while transporting it. Packaging also helps to facilitate storage and also helps in advertising and sales promotional activities. Besides, it is responsible for increasing demand and profits of an organization.

Advantage of middleman: Packaging will help the middlemen to store the product in is proper place. Based on the packaging, it will be easy to exhibit it before the customers. By Looking at the packaging, the workers working in a warehouse will be able to understand what is inside the package and they will be able to handle it accordingly.

Advantages of customers: Packaging will reduce the chances of tarnishing and it is also helpful in providing important knowledge about the product and the organization that manufactured it. It also includes steps and instructions from which customers will be able to understand the procedure through which the product will be used.

Labelling is not different from packaging and all its advantages are nearly same as the advantages of packaging. Labelling will allow the manufacturing organization which is Nike to give a clear instruction about the users of the product. As a result of labelling, the manufacturing organization can make sure that the product is being sold by its original price. Labelling also helps to develop manufacturer and buyer relation. As a result, manufacturers are encouraged to develop only standard products which buyers can easily identify. Besides, from labelling, a user can get various types of information about the product like the date of manufacturing and the date of expire. However, in case of Nike this advantage will not count, However, by the process of labelling a user will be able to understand if this product will meet his demands or not.

In case for labelling, if the customer is illiterate it will not help him to understand the product and its features. Besides, adding a proper label that will include every bit of information about the product will increase the cost of the product (Tachizawa and Wong 2015). On the other hand, labelling is only effective where standardization is compulsory. Sometimes labelling becomes the only tool for the customers to compare it with other product. Most of the customers do not even bother to use it to feel its performances. This eventually ends in abandonment of a product in support of the other.

In case of packaging, the main reason of its disadvantage is the cost associated with it. According to Porteous and Rammohan (2013), packaging can increase price of a product up to 40% of the selling price. On the other hand, packaging is accountable for important portions of the waste stream. A report published by Ashland Food Cooperative, packaging is alone responsible for one third of land filling the United States. It is also true that products that use more packaging consume more resources production. It is found that nearly 12 million barrels of oil are used to make water bottles and one pound of polystyrene uses about two pounds of stock of petroleum. Another biggest advantage of packaging in distributive centre rather than in factory will come from the distributive company. Distributive organizations also look for ways to promote their brand image and they choose the products to do so (Xiao et al. 2014). So many times it is seen that the distribution company has repacked a product by using their logo in order to improve their brand image towards the customers. Besides, in some cases it is also seen that distribution organization are changing the labels related to the price of the products as per their requirement. This will hamper the brand image o the manufacturing organization and they will lose the loyalty of the customers.

From the above discussion, it is clear that packaging and labelling has both advantages and disadvantages. However, it is true that it is not possible to transport a product without giving it proper packaging and labelling in order protect is from theft and misuse.

According to the traditional definition, the material handling services are considered as the activities for storing, protecting, controlling as well as moving the materials throughout various operational divisions. These divisions can be ranged from customer provision, distribution, and disposal as well as manufacturing. Just like any other service it also includes several major advantages as well as disadvantages, while Nike’s operational success is concerned (Martel and Klibi 2016). The major advantages of the material handling services are described below:

Nike will be able to control the distribution of the materials properly so that there will be limited chance of any accident. The company effectively focuses on careful handling of the materials, which help them to avoid any kind of hindrance regarding the supply of the materials to the customers as well as various divisions of the operation (Ivanov et al. 2016). Besides, it is also important to protect the products from theft or the prevention of misuse. Material handling will help Nike to eliminate those problems while it is transported to consumers or to any distribution centre.

Nike will be also able to reduce the effort and stress associated with the supply operation of the company’s materials. In this context, it has been identified that Nike highly emphasize on eradication of the factors, which are challenging as well as risky for the supply operation. These factors are mostly ineffective workers as well as non-functional equipment (Albert et al. 2014).

Nike will be able to make the distribution, manufacture as well as storage operation less time consuming. In order to do that, the company focuses on good material handling with relevant and scientific techniques. It will eventually make the supply operation more easy and quick (Distelhorst et al. 2014). It is already discussed that the organization is even using satellite systems to enhance their supply chain management This system will help the organization to handle their storage operations in a better way.

The company will be able to identify the unnecessary work, which accumulates with the retail centre based supply chain management. In this context, it is freely acknowledged that company’s material handling service will be able to minimize the work and stress. The company can thereby terminate extra workers in an efficient fashion (Martel and Klibi 2016).

The extensive study of the supply chain management of Nike has been able to indicate several crucial disadvantages, which plays a very crucial influence on the company’s performance. These disadvantages are discussed below:

In order to implement the material handling services properly, Nike will need to initiate several crucial technological systems. In this context, the company will need an experienced and efficient workforce (Ivanov et al. 2016). However, this scenario makes the supply chain management mostly dependent on the technical employees.

Management of logistics:

As the company is solely responsible for supplying the materials to various operational divisions such as distribution, provision, storage as well as manufacture, they have to work on a very wide-ranging database (Albert et al. 2014). This particular scenario presents a greater concern for the company, as a singly mistake has the potential of high loss.

Security of the supply chain:

Security for the material handling service poses most critical concern for the company. In this context, it has been identified that the company have to focus on greater supervision and surveillance so that company can avoid any kind of thievery or fraudulent acts (Distelhorst et al. 2014).

References

Ageron, B., Gunasekaran, A. and Spalanzani, A., 2012. Sustainable supply management: An empirical study. International Journal of Production Economics, 140(1), pp.168-182.

Albert, P.J., Werhane, P. and Rolph, T., 2014. Global Corporations and Supply Chain Management. In Global Poverty Alleviation: A Case Book (pp. 321-348). Springer Netherlands.

Buddress, L., 2013. Managing Supply Chain Sustainability and Risk: Keys to Success. Strategic Management, 18(2), pp.3-16.

Cruz, J.M., 2013. Mitigating global supply chain risks through corporate social responsibility. International Journal of Production Research, 51(13), pp.3995-4010.

Distelhorst, G., Hainmueller, J. and Locke, R.M., 2014. Does lean improve labor standards? Capability building and social performance in the Nike supply chain. Watson Institute for International Studies Research Paper, (2013-09).

Distelhorst, G., Hainmueller, J. and Locke, R.M., 2016. Does Lean Improve Labor Standards? Management and Social Performance in the Nike Supply Chain. Management Science.

Harms, D., Hansen, E.G. and Schaltegger, S., 2013. Strategies in sustainable supply chain management: an empirical investigation of large German companies. Corporate Social Responsibility and Environmental Management, 20(4), pp.205-218.

Hoejmose, S., Brammer, S. and Millington, A., 2013. An empirical examination of the relationship between business strategy and socially responsible supply chain management. International Journal of Operations & Production Management, 33(5), pp.589-621.

Ivanov, D., Tsipoulanidis, A. and Schönberger, J., 2016. Global Suppy Chain and Operations Management. Springer,.

Kozlenkova, I.V., Hult, G.T.M., Lund, D.J., Mena, J.A. and Kekec, P., 2015. The role of marketing channels in supply chain management. Journal of Retailing, 91(4), pp.586-609.

Lemke, F. and Petersen, H.L., 2013. Teaching reputational risk management in the supply chain. Supply Chain Management: An International Journal,18(4), pp.413-429.

Martel, A. and Klibi, W., 2016. Supply Chains: Issues and Opportunities. InDesigning Value-Creating Supply Chain Networks (pp. 1-43). Springer International Publishing.

Porteous, A. and Rammohan, S., 2013. Integration, Incentives and Innovation Nike’s Strategy to Improve Social and Environmental Conditions in its Global Supply Chain.

Pullman, M. and Collins, D.E., 2013. Reshaping the Operations and Supply Chain Management Core Class Curriculum to Include Business Sustainability. Operations Management Education Review, 7.

Qrunfleh, S. and Tarafdar, M., 2014. Supply chain information systems strategy: Impacts on supply chain performance and firm performance.International Journal of Production Economics, 147, pp.340-350.

Ross, D.F., 2013. Competing through supply chain management: creating market-winning strategies through supply chain partnerships. Springer Science & Business Media.

Sajjad, A., Eweje, G. and Tappin, D., 2015. Sustainable Supply Chain Management: Motivators and Barriers. Business Strategy and the Environment, 24(7), pp.643-655.

Schaltegger, S. and Burritt, R., 2014. Measuring and managing sustainability performance of supply chains: Review and sustainability supply chain management framework. Supply Chain Management: An International Journal, 19(3), pp.232-241.

Shi, M. and Yu, W., 2013. Supply chain management and financial performance: literature review and future directions. International Journal of Operations & Production Management, 33(10), pp.1283-1317.

Tachizawa, E.M. and Wong, C.Y., 2015. The performance of green supply chain management governance mechanisms: A supply network and complexity perspective. Journal of Supply Chain Management, 51(3), pp.18-32.

Xiao, T., Choi, T.M. and Cheng, T.C.E., 2014. Product variety and channel structure strategy for a retailer-Stackelberg supply chain. European Journal of Operational Research, 233(1), pp.114-124.

Xu, G., Dan, B., Zhang, X. and Liu, C., 2014. Coordinating a dual-channel supply chain with risk-averse under a two-way revenue sharing contract.International Journal of Production Economics, 147, pp.171-179.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2018). Nike Logistic Management & Strategy Analysis. Retrieved from https://myassignmenthelp.com/free-samples/logistic-management-and-strategy-of-nike.

"Nike Logistic Management & Strategy Analysis." My Assignment Help, 2018, https://myassignmenthelp.com/free-samples/logistic-management-and-strategy-of-nike.

My Assignment Help (2018) Nike Logistic Management & Strategy Analysis [Online]. Available from: https://myassignmenthelp.com/free-samples/logistic-management-and-strategy-of-nike

[Accessed 25 February 2026].

My Assignment Help. 'Nike Logistic Management & Strategy Analysis' (My Assignment Help, 2018) <https://myassignmenthelp.com/free-samples/logistic-management-and-strategy-of-nike> accessed 25 February 2026.

My Assignment Help. Nike Logistic Management & Strategy Analysis [Internet]. My Assignment Help. 2018 [cited 25 February 2026]. Available from: https://myassignmenthelp.com/free-samples/logistic-management-and-strategy-of-nike.