Application / Goal

Find a real-world (household, etc.) control system that uses some kind of transducers and describe the characteristics of the system following the format

below.

(a) What is the system for? Describe the application/goal of the system?

(b) What sensors (transducers) are used in the system? (note: the answer is expected to be more than just “displacement sensor” but more detailed, such as LVDT, optical shaft encoder, etc.) Briefly describe the mechanism, expected input

range and output accuracy.

(c) Why is this type of transducer used and is there any alternative? (d) Describe expected nature of the signal output from the transducer (e.g. level of voltage/current, noise level, etc.). What kind of signal conditioning is needed?

(e) Draw the block diagram, show controller/plant and the input/output measured variables.

(f) How much does it cost, what is the most expensive part?

(g) Discuss the accuracy of the whole system, considering its intended application.

(h) Discuss the limitation of the control system and how it could be improved. Considering these improvements and the intended application, why have the designers not included them in the design?

The washing machine is used to wash the clothing and sheets. It washes the clothes using water. These washing machines are used to wash the clothes in two ways, top load, and front load.

The application or goal of the washing machine is to perform the series of tasks like washing, rinsing and spinning to complete the washing of cloths. The machine is designed with the goals of performing the following three tasks.

Washing

Many of the washing machines include internal electrical heating elements to heat the water used for washing. It is useful as the rate of cleaning action of the detergent can be increased. Special detergents are used for the washing machine towards releasing different ingredients of chemicals at various temperatures. Not all machines use the electrical heaters and cold water filling is done, as the cold water washing is safe for the biological detergents.

Rinsing

After washing of the cloths with the chemical detergents is completed, the process of rinsing is started. Rinsing is performed multiple time after washing with the detergents. There must be a trade-off between usage of more water and a number of rinsing cycles.

Spinning

Spinning, especially, with high speed can remove more water, which eventually leads to dry the clothes faster. In some of the machines, heated cloth-driers are also used to increase the drying rate of the cloths. The machine spins the tubs with the speed equal to or less than 700 rotations per minute.

Sensors

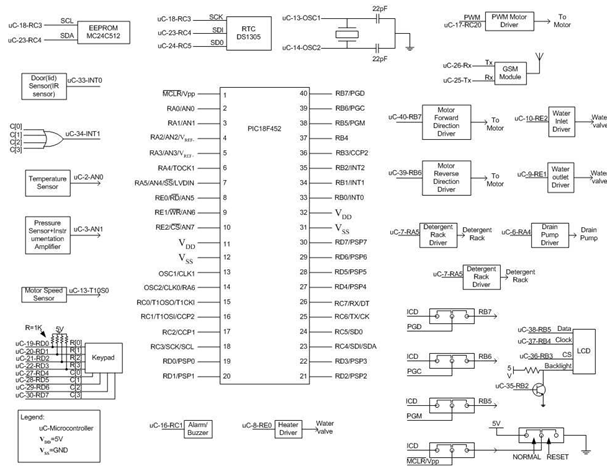

Washing machines use many sensors in order to perform the three functions called washing, rinsing and spinning to wash the clothes. The machine uses the control systems to perform these tasks. The control system is established in the machine for controlling the motor, which is the crucial part of the design of the machine. The control system of the washing machine is controlled by the PWM(Phase Width Modulation) feature, related to the microcontroller.

The first and important sensor used in the washing machine is the motor speed sensor, which is well interfaced with the microcontroller. The sensor is used to read the speed of the motor and passes the signals to the motor to control the speed accordingly. The reading and control of the speed of the motor are done differently during different phase of the washing processes.

Motor direction driver circuit is used to determine the motor direction. When the motor rotates in the forward direction, the current is driven in the forward direction and eventually, the motor is rotated forward. In contrast to that, the motor reverse direction driver makes the motor rotate in the reverse direction. The overall speed is controlled with the help of the PWM driver.

The door sensor is kept at the highest priority. When the door or the lid is opened, the sensor immediately raises the external interrupt 0, with the highest priority. The output of this sensor goes low when the door is open and the operation of the machine does not start. Then the alarm is activated to close the door.

The pressure sensor is an important sensor that continuously senses the amount of water. If the filled water is less than water to be filled, it continues, else inputs the microcontroller to exit. It indicates fill tub. It also controls the operation of the drain, by continuing the water drain, until the water level is not empty.

Stain sensor senses the quality of the clothes instantaneously. The sensor gives the inputs to the microcontroller, about the wash cycles, the amount of water, the time required, accordingly for optimization. It is enabled in fully automatic mode.

The sensor analyzes the level of dirt using two test tubes that contain LED and LDR. When the dirt is more, means when it is more opaque, light focused from LED will be less, and the LDR resistance increased. Eventually, the voltage across LDR reduces, showing the level of the dirt.

Specifications

The temperature sensor is used to sense the temperature of the water and then sends input to the microcontroller to control the water heater operation.

The sensor works and enables automatic washing machine valves of water shutoff. When the water leaks hot and cold water valves will be closed.

The sensor checks the power input continuously and if the power failures, it indicates the necessary function.

The sensor detects the volume of the laundry load accordingly helps to control the water amount to load.

There are analog input channels, like AN2, AN3 and AN4 set and reserved in washing machines so that additional sensors can be added to upgrade the control system of the washing machine.

Switching voltage ranges from 190 to 260V and

Breakdown voltage ranges to approx. 320 V

Switching current is 0.5 A

Carry Current is 1.5 A

Operating time = 0.5 milli seconds

Release time = 0.1 milli seconds

Storage temperature ranges from -20 to 850C

Operate temperature ranges from -35 to 850C

Dynamic Contact Resistance = 200 milli Ohms

Static Contact Resistance = 150 milli ohms

Contact Rating is 10 W

The transducers used are for temperature, pressure, stain, door and motor speed sensors. These transducers are used as the most effective ways to measure the actual input parameters as well as the desired input parameters. The reasons for using the sensors are for better accuracy and longer working life

There are alternatives to the sensors, where the function of the sensors can be replaced. The alternative is the micro switch or reed switch. For instance, the door open sensor can be replaced by the micro switch. A reed switch can also be used to sense whether the door is closed or not.

(d) Describe expected nature of the signal output from the transducer (e.g. level of

voltage/current, noise level, etc.). What kind of signal conditioning is needed?

Let us consider thermal sensor in the washing machine. Thermal sensors are the semiconductor junction diodes that provide the output signal, according to the thermal sensing properties.

The output current signal is given as

I = I0(eqV/kT -1)

Where

I0 = T3/2 e –qVg/kT,

I = current

k = Boltzmannas constant

T = Temperature

q = constant

V = Voltage

The thermal sensors made of semiconductor material has the temperature range of -40 to 150 ¡C

The output signals are either in current or voltage form.

Reason For Using These Transducers

Commercial temperature sensors are available with the temperature range of -400 C to 10000 C.

Signal Conditioning

The process of signal conditioning of the sensors in the washing machine is done in multiple stages.

Filtering – It is the first stage of the signal conditioning. Washing machines are given the mains power with 50 or 60 Hz frequency. Filtering is done to extract the valid data needed from the signal frequency spectrum. Along with the signal or valid data extraction, noise levels may also be increased.

Amplifying – There are two important functions of the amplification in the sensors of the washing machine. The first function is to increase the resolution that is available with the input signal and along with that the signal-to-noise ratio will also be increased. The output level may not sufficient for the ADC or Analog-to-Digital converter to process. In such cases, it is important to increase the output voltage level that is sufficient for the ADC. For example, an electronic temperature sensor of the washing machine may produce the output in millivolts that may not be sufficient for the ADC to process to volts and amplification can help to increase the level of voltage. Programmable gain amplifiers or instrumentation amplifiers are used in the sensors of the washing machine.

Isolation – Isolation is done after the amplification stage to pass the output measured signal from the source towards the device used for measuring, all without need for the physical connection. The advantage of isolation here is the isolation of the signal perturbations sources possibly. For washing machine sensors, either optic isolation or magnetic isolation can be used.

The overall function of the washing machine can be described as below.

The washing machine system is to be operated with single phase AC that varies the voltage from 10VAC to 250 VAC. The system has to be enabled itself to protect the system against the variations of the power supply.

The washing machine provides three modes of operation, called fully automatic, semi-automatic and manual. The preference of mode is taken from the keypad.

When the fully automatic mode is chosen, intervention of user requirement must be nil. The system should start the work automatically, operate until the end automatically and at the end of the operation, the machine must notify the end of the operation to the user.

The sensors sense the quantity of cloth, water temperature, load, the requirement of water, detergent required and wash cycle time, according to the mode selected.

Alternatives

In the semi-automatic mode also, the requirement of the user is nil. However, certain washing conditions must be specified. Then the system has to perform according to the specifications and notify the user at the end of the operation.

In the manual mode, the user has to continuously specify the kind of operation to the machine related to the control system. For instance, the user has to specify wash only option and the corresponding control system information like load, amount fo water, wash time, etc. After completion of the operation, the system has to notify the user.

Importantly, when the door or lid is opened, it should system should stop working, in less than 10 seconds.

The washing machine has to provide the basic features such as washing, hot wash, cold wash, rinsing, spinning, etc.

The system has an easier possibility of upgradeability with new features. Both the hardware and software must be compatible with fewer and more features. When any feature is removed, the rest of the features should not get affected, not disturbing the overall operation of the system.

When the power failure occurs, the machine has to restart its operations from where it was stopped, after the power is resumed.

Many sensors give the input to the microcontroller, and the microcontroller sends the input accordingly to the respective devices. Sensors provide the output to the instrumentation amplifier, eventually bringing the output voltage levels in the range from 0V to 5V.

The microcontroller is the most expensive part of the washing machine. It is around 5000 to 6000 USD.

Washing machines are very accurate machines, where the accuracy of the operation, right from voltage, current, water level, every aspect is considered as an accurate system. That is why the applications of the washing machine can be extended to washing the clothes, without the presence of the user.

Question (h)

Automatic washing machines run on the basis of open loop control system and run the machine according to the pre-set time to perform the tasks of washing the cloths. Though there are good number of control systems, like they can help in finding the solutions for many regular and tedious tasks and security problems for accurate measurements there can be associated limitations that they may cause problems as they can set off any point of time. Though the washing machines are highly reliable and can work human-independent, they can easily cause problems and become dangerous.

These limitations of the control systems can only be improved through usage of the reliable transducers, like all kinds of sensors in this case of the washing machine. The reliability of the sensors can be improved with the additional design of alarm system, where the operational issues of the sensors are risen. Most of the washing machines are very reliable, as they operate human independent. However, better designs with the additional alarm system can minimize the catastrophes by the operation of the washing machines.

The washing machine uses the open loop control system. The negative loop of the control system can be useful and can improve the control system used in the washing machines.

Negative feedback and closed loop systems cannot be used as the gain need to be more and there must be adequate output for operation of the washing machine.

References

Embedded System for Automatic Washing Machine Using Microchip PIC18F Series Microcontroller, [Online]. Available at https://www.idc-online.com/technical_references/pdfs/electronic_engineering/Embedded_System_PIC18F_Series_Microcontroller.pdf. Accessed on 11 February 2016.Walerie-Anne Giscard d’Estaing. The Second World Almanac Book of Inventio New York; Pharos Book, 1986.

A. Grimes, E. C. Dickey, and M. V. Pishko (2006), Encyclopedia of Sensors (10-Volume Set), American Scientific Publishers

David John Cole, Eve Browning, Fred E. H. Schroeder, Encyclopedia of Modern Everyday Inventions, Greenwood 2003

David Harris & Sarah Harris (2012).Digital Design and Computer Architecture, Second Edition

Heath, Steve (2003).Embedded systems design. EDN series for design engineers (2 ed.). Newnes.

Agarwal, Anant. Foundations of Analog and Digital Electronic Circuits.Department of Electrical Engineering and Computer Science, Massachusetts Institute of Technology, 2005

Hristu-Varsakelis and W. S. Levine (Ed.): Handbook of Networked and Embedded Control Systems, 2005

Dong, and W,-J. Kim, “Markov-chain-based Output Feedback Method for Stabilization of Networked Control Systems with Random Time Delays and Packet Losses,” International Journal of Control, Automation, and Systems, vol. 10

C. Martins, M. A. Dahleh and N. Elia, "Feedback stabilization of uncertain systems in the presence of a direct link," IEEE Transactions on Automatic Control, Volume 51, Issue 3, 2006

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2017). Real-World Control System Using Transducers: Washing Machine. Retrieved from https://myassignmenthelp.com/free-samples/automatic-washing-machine-microchip-pic18f-series.

"Real-World Control System Using Transducers: Washing Machine." My Assignment Help, 2017, https://myassignmenthelp.com/free-samples/automatic-washing-machine-microchip-pic18f-series.

My Assignment Help (2017) Real-World Control System Using Transducers: Washing Machine [Online]. Available from: https://myassignmenthelp.com/free-samples/automatic-washing-machine-microchip-pic18f-series

[Accessed 31 May 2025].

My Assignment Help. 'Real-World Control System Using Transducers: Washing Machine' (My Assignment Help, 2017) <https://myassignmenthelp.com/free-samples/automatic-washing-machine-microchip-pic18f-series> accessed 31 May 2025.

My Assignment Help. Real-World Control System Using Transducers: Washing Machine [Internet]. My Assignment Help. 2017 [cited 31 May 2025]. Available from: https://myassignmenthelp.com/free-samples/automatic-washing-machine-microchip-pic18f-series.