High Gain Feedback Control for Rigid Robot

Question:

Discuss about the Control System for The Robotic Joint.

The excessive feedback procurement has precise disturbance rejection, robustness and tracking abilities within the inflexible frame case. It is applicable to hold those functions whilst the joints are significantly flexible. This study examines the feedback control system for the robot with very flexible joints. The feedback is done from DH joint angles in the robot. The Robot is like an open kinematic series with some revolute joints. The Joints are demonstrated as direct torsional springs as well as joint damping is very small. The Drives are appended at all the joints. Since, the engine edges are presently not as same as the connection points, the feedback from the drive side of the adaptable joints is diverse with the feedback input from the connection side of the adaptable joints. For settled 0 angle with nonlinear terms might be taken as an unsettling influence, the exchange work from the drive torque to engine point has just limited zeros while the exchange work from the drive torque to connection edge has some unbounded zeros. The settling control rules and laws for the quick elements are acquired, while utilizing inputs two arrangements are proposed. The Expecting joint torque can be measured, a joint torque control law can balance out the quick progression then again a compensator can be intended to specifically balance out the quick flow in the quickening feedback circle.

The criticism of high pick up has great unsettling influence dismissal power concerning plant and load varieties and great following capacity. The high pick up speeding input for an inflexible body, robot is like the registered torque or criticism linearization control law. Criticism is utilized as 'work bolstered by NSERC Canada give a number 4394 to change the inflexible body progression into R paired twofold integrators. The second control rule is then used to control the integrators rather being dropping the nonlinear terms, which are presently an unsettling influence to be rejected or around crossed out ("Shifting an Object by Robot Using Haptic Shared Control System", 2016). For a perfect unbending body, the speeding up input will bring about a stable shut circle framework. With the inflexible joints, quickening input from the connection side is as same as speeding up criticism from the drive side of the joint (Rigelsford, 2003). With an adaptable joint robot, engine edges are presently extraordinary from the connection points. In this manner, the increasing speed input from the drive side of the adaptable joints is distinctive to quicken the criticism from the connection side of the adaptable joints. For settled 0 and with the non-linear terms considered as aggravations, the exchange work from drive torque to engine point has just limited zeros while the exchange work from drive torque to connection edge has some unending zeros (Recent progress in robotics: viable robotic service to human, 2011). The high pick up in the speeding criticism circle from the connection points can be destabilized because of the nearness of joint flow. The Settling control laws for the quick flow are acquired, when utilizing the speeding up input, two arrangements are proposed. It is sensible to accept that more updated eras of engines will be accessible when factory incorporates both torque angle edge estimations. Accepting the joint torque can be measured. A joint torque control law can balance out the quick progression or on the other hand, a compensator can be intended to specifically settle the quick flow in the quickening input circle (Wang, Dong, & Bai, 2010). The shut circle data transfer capacity of the robot flow can then be expanded while holding the helpful properties of speeding up input, for example, vigor and aggravation dismissal (Petkovic, Pavlovic, & Issa, 2013). Presently, there are two extensive parameters related to the quick clynanics, joint solidness and speeding up pick up. A lot of study has centered the control of flexible joint robots. The starting from the main control techniques produced for inflexible body controllers, there are some intense theoretical results concerning the management and control of all the controllers with joint versatilities. These incorporate particular perturbation and fundamental complex, input linearization, and dynamic criticism linearization alongside the versatile control systems. The basic complex and solitary annoyance systems take care of the control issue by the two phase procedure (Metelskii, 2015). They propose a quick joint torque control circle, relating to the quick part of the controller elements, and a slower external control circle compared to the inflexible body flow of the robot. A control framework for accomplishing rapid torque for a joint of a robot incorporates a printed circuit board get together (PCBA) having an assembled joint processor and fast correspondence transport. The PCBA might likewise incorporate a PIM and neighborhood SCE for handling sensor information from at least one engine position sensors (Weinberger, & Braatz, 2014). Torque control of an engine of the joint is given by means of the PCBA as a rapid torque circle. Each joint processor might be installed inside or assembled with the mechanical joint being controlled ("Shifting an Object by Robot Using Haptic Shared Control System", 2016). The Collocation of the joint processor, PIM, and rapid transport may expand commotion invulnerability of the control framework, and the limited handling of sensory information from the joint engine at the joint level may limit transport cabling to and from the each control hub. The joint processor may incorporate the FPGA (Katayama, 2015).

Feedback Control for Robot with Flexible Joints

The criticism control procedures utilize estimation and estimation of the framework state to diminish vibration. Criticism control, utilize estimation or estimation of the framework states as a contribution of the controller close to the reference an incentive to decrease the vibration(Hernandez-Santos, Rodriguez-Leal, Soto, & Gordillo, 2012). The Feedback controllers can be intended to be strong to parameter vulnerability. For adaptable controllers, bolster forward and criticism control procedures are utilized for vibration concealment and position control, individually. A worthy framework execution without the vibration that record for framework changes can be accomplished by building up a mixture controller comprising of both control strategies. Subsequently, an appropriately planned encourage forward controller is required, with which the multifaceted nature of the required criticism controller can be decreased. These strategies depend on the exact framework model and make the framework exceptionally touchy to demonstrate blunders that can influence the framework performance. Various methods have been proposed to encourage the forward control procedures for the control of vibration (Haddad, 2015). Swings has inferred a moulded torque, which limits the leftover vibration and the impact of parameter varieties that influence the modular frequencies. In any case, the constraining capacity is not time-ideal. A few analysts have concentrated the use of registered torque systems for the control of adaptable manipulators. Be that as it may, this strategy experiences a few problems.

Position as well as Velocity Sensors: The Position sensors are the input gadgets used to discover the exact development of joints for fulfilling the required bearing and position of the end effector. A robot requires speed sensors for controlling the speed of the controller development (Fujita, 2012). The Position sensors utilize a few gadgets, for example, resolvers, potentiometers, and encoders for detecting the position, while the speed sensors incorporate DC tachometer for giving proper speed. Every single robot requires input gadgets for conveying the exact speed control. Indeed, even as of late created entangled control framework additionally scarcely depends on these gadgets for increasing the better execution of the robot controller in a few errands like deceleration and speeding up.

Actuators as well as Power Transmission Systems: A controller utilizes the actuators along with the power transmission framework for accomplishing the control activities. Thus, these gadgets help in producing power for moving the robot arm. The actuators are utilized to give energy to the robot joints with the assistance of the power transmission frameworks (Fred, Filipe, & Gamboa, 2010). Now and again, the power transmission frameworks won't be required if the actuators are connected to the robot joints itself. A portion of the gadgets that are utilized as the actuators are pneumatic, water powered, and electric (Goodwin, Graebe, & Salgado, 2011). The power transmission frameworks make utilization of apparatuses, screws, as well as pulleys for playing out this instrument.

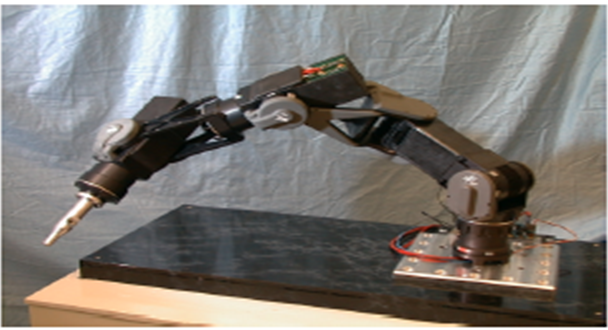

The two very light-weight robots created at the DLR are extremely appropriate for the execution and testing of the control calculations described in the previous area. By outlining profoundly incorporated mechanical and electrical segments, a heap to possess weight proportion of ≈ 1:2 is accomplished, for a robot weight of 17kg. For joint control, the engine position and the joint torque signals in light of strain gage innovation are accessible (Fischer, 2010). The new robot is furnished with connection position sensors also. Moreover, a 6 DOF drive torque sensor is incorporated in the robot's wrist. Both robots are excess 7 DOF controllers. The utilization of a ?oating point flag processor for each joint controller as well as very fast optical communicating bus (1ms) between the joints and the robot controller gives the essential ?exibility and registering power for included control calculations (Ellis, 2016).

Torque Control Laws for Quick Dynamics

Fig. 1:DLR light-weight joint robot

Image Source:alin.com

For the design of the controller, we can start by considering the robot model proposed by Spong:

τm = J¨ q1 + τ + DK−1 ? τ +τF (1)

τ +DK−1 ? τ = M(q2)¨ q2 + C(q2, ? q2)? q2 + g (q2)(2)

τ = K(q1 −q2) (3)

Where, τm is the engine torque vector, q1 and q2 the engine and connection positions, separately, and τ the joint torque. J is the engine idleness grid, K and D, are the flexibility and damping frameworks, brought about predominantly by the rigging box and the torque sensor (Hernandez-Santos, Rodriguez-Leal, Soto, & Gordillo, 2012). These lattices are inclining and positive de?nite. M, C and g are the same with respect to sti? robots: the mass grid, the Coriolis and centripetal torque vector and the gravity vector. In these conditions, the active vitality of the rotors because of connection developments is ignored, just the dynamic vitality because of their own pivot being considered. For the diminishment proportion of 160 of our robots, this is a decent estimate. τF is the grinding power vector (Deng, Li, Zheng, & Yao, 2011).

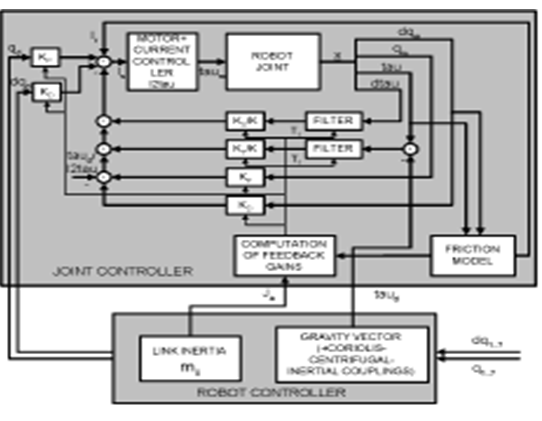

Fig. 2:Controller stucture

Image Source:

A noteworthy reasonable stride for the execution of the proposed controller structure is the parameter identi?cation. Due to the huge number of parameters, we partitioned them in a few gatherings which were identi?ed independently. The robot’s kinematic and element parameters are correctly processed utilizing the current mechanical CAD projects, and estimation based advancement of these parameters brought no significant upgrades. The rubbing parameters were identi?ed in view of the current, torque and speed estimations on significant directions for the entire robot. Although the characteristics of the current controlled engines can be identi?ed together with the rubbing parameters, this prompts an awful molding of the advancement issue. Accordingly, the engine parameters were likewise identi?ed independently utilizing an engine test-bed. The FEM assessment for the joint flexibility were not sufficiently exact, so we decided it from the joint wavering recurrence, knowing the latency. Then in the robot, the available sensors enable online computation of the versatility. The identi?cation brought about an exceptionally correct reproduction, which is utilized for the outline and trial of the controllers.

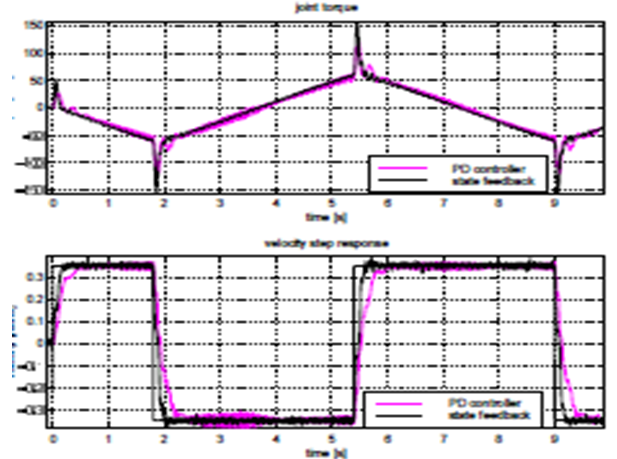

Fig. 3:Feedback control of robot

Image Source: alin.com

Conclusion

This study concludes that a state feedback controller for the ?exible joint robots can be stretched out bit by bit to assess the full robot flow. It has been demonstrated that even with the basic, ?xed pick up the controller, the joint can be balanced out around a reference position and the oscillations brought on by the joint ?exibility are effectively damped. Contrasted with different controllers, this one is e?cient for all intents and purposes and simple to execute notwithstanding for some DOF, and still hypothetically be very much established. The effectiveness of the controller is approved through the examinations on the DLR light-weight robots.

References

Built-in PLC makes Cartesian robot cell a tool for complete system control. (2014). Industrial Robot: An International Journal, 31(1).

DENG, Z., LI, X., ZHENG, K., & YAO, W. (2011). A Humanoid Robot Control System with SSVEP-based Asynchronous Brain-Computer Interface. ROBOT, 33(2), 129-135.

ELLIS, G. (2016). Control system design guide (1st ed.). [Place of publication not identified]: ELSEVIER BUTTERWORTH-HEIN.

Fischer, I. (2011). A geometric method for determining joint rotations in the inverse kinematics of robotic manipulators. Journal Of Robotic Systems, 17(2), 107-117.

Fred, A., Filipe, J., & Gamboa, H. (2010). Biomedical engineering systems and technologies (1st ed.). Berlin: Springer.

Fujita, M. (2012). Robot Behaviour Control System and method, and robot apparatus. The Journal Of The Acoustical Society Of America, 132(4), 2779. Goodwin, G., Graebe, S., & Salgado, M. (2001). Control system design (1st ed.). Upper Saddle River, N.J.: Prentice Hall.

Haddad, F. (2015). Robotic surgery: edge of tomorrow?. The Bone & Joint Journal, 97-B(3), 289-290.

Hernandez-Santos, C., Rodriguez-Leal, E., Soto, R., & Gordillo, J. (2012). Kinematics and Dynamics of a New 16 DOF Humanoid Biped Robot with Active Toe Joint. International Journal Of Advanced Robotic Systems, 1.

Katayama, H. (2015). Output Feedback Stabilizing Controllers for Nonlinear Sampled-Data Strict-Feedback Systems. SICE Journal Of Control, Measurement, And System Integration, 8(2), 94-98.

Metel’skii, A. (2015). Feedback control of the spectrum of differential-difference system. Automation And Remote Control, 76(4), 560-572.

Petkovic?, D., Pavlovic?, N., & Issa, M. (2013). Passively compliant robotic joint with embedded sensors (1st ed.). Saarbru?cken: LAP LAMBERT Academic Publishing.

Recent progress in robotics: viable robotic service to human. (2008) (1st ed.). Berlin.

Rigelsford, J. (2013). Control system. Industrial Robot: An International Journal, 30(2).

Shifting an Object by Robot Using Haptic Shared Control System. (2016). International Journal Of Science And Research (IJSR), 5(5), 177-180.

Wang, J., Dong, L., & Bai, Y. (2010). State Feedback Controller Design for Exponential Stability of Networked Control System. International Journal Of Computer And Electrical Engineering, 203-207.

WANG, J., YANG, C., WANG, Z., WANG, Q., & SONG, T. (2010). Wireless Measurement and Control System for a Novel Bionic Micro-Robot. ROBOT, 32(1), 34-40.

Weinberger, M., & Braatz, R. (2014). A Real Nobel Prize for a Feedback Control System: Simon van der Meer [Feedback]. IEEE Control Systems, 34(2), 14-14.

XIE, L., WANG, Z., WANG, C., & XU, J. (2010). A Robust Walking Control System of Humanoid Robot. ROBOT, 32(4), 484-490.

Zhang, Z. (2012). Design Optimization of a Cable-Driven Two-DOF Flexible Joint Module. International Journal Of Advanced Robotic Systems, 1.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2018). Feedback Control System For Robot With Flexible Joints. Retrieved from https://myassignmenthelp.com/free-samples/control-system-for-the-robotic-joint.

"Feedback Control System For Robot With Flexible Joints." My Assignment Help, 2018, https://myassignmenthelp.com/free-samples/control-system-for-the-robotic-joint.

My Assignment Help (2018) Feedback Control System For Robot With Flexible Joints [Online]. Available from: https://myassignmenthelp.com/free-samples/control-system-for-the-robotic-joint

[Accessed 23 May 2025].

My Assignment Help. 'Feedback Control System For Robot With Flexible Joints' (My Assignment Help, 2018) <https://myassignmenthelp.com/free-samples/control-system-for-the-robotic-joint> accessed 23 May 2025.

My Assignment Help. Feedback Control System For Robot With Flexible Joints [Internet]. My Assignment Help. 2018 [cited 23 May 2025]. Available from: https://myassignmenthelp.com/free-samples/control-system-for-the-robotic-joint.