Discuss about the case study Operations Management for Manufacturing Process of Samsung Electronics.

Manufacturing process is one of the major aspects for producing a new product. In the current paper, the manufacturing process of Samsung Electronics has been discussed in an evaluated fashion. In order to do that, the brief discussion of the Samsung Electronics has been depicted ina clear and precise manner. In the same context, the paper also includes an acute concept of the manufacturing process. The paper has discussed every single aspect of Samsung Electronics' manufacturing process with utmost clarity.

In addition to that, the paper has also depicted as well as evaluated the process map of Samsung’s manufacturing system. The analysis of manufacturing process of Samsung has been done on the basis of several operations performance objectives, i.e. quality, cost, dependability, speed as well as flexibility. After the analysis, the paper has also been able to provide several useful recommendations to improve the manufacturing process in terms of the operations performance objectives. This way the paper has clearly reflected the scenario of the manufacturing process in Samsung Electronics.

Samsung was founded in the year of 1938 by Lee Byung-chull as a company of trades. Samsung crossed the threshold of the electronics industry in the time-period of late 1960. Samsung Electronics is one of the most important subsidiaries that maintain the electronics business. After entering the electronics divisions, the company developed four different groups of electronics-centered business, which are Samsung Electro-Mechanics, Samsung Electronics Devices, Samsung Semiconductor and Telecommunications as well as Samsung Corning. Samsung Electronics launched a black-and-white television set as its first product. In the year of 1987, Samsung Group was taken apart into four distinct individual business entities, which are Samsung Group, CJ Group, Hansol Group as well as Shinsegae Group (Hwang and Choung 2014).

There are four primary divisions those are operated by Samsung Electronics of Samsung Group. These divisions are Semiconductors, Digital Media, Home appliances as well as Information & Communications. Samsung Electronics operates its business through various products such as video equipment, televisions, audio equipment, phones, computers, associated appliances, fax machines, factory automation products. In addition to that, there are various other products such as cellular phones, fiber optics products, closed circuit security products, semiconductors, solar energy systems as well as motors and compressors. In the contemporary world, Samsung Electronics has experienced severe competition in the electronics market. The major competitors are Matsushita Electric Industrial Co. Ltd, LG Group as well as NEC Corporation. Although, the company has experienced several challenges at the beginning of 21st century, Samsung Electronics maintained its stand in the electronics industry (Hwang and Choung 2014).

Concept of Manufacturing Process

Figure 1: Logo of Samsung Electronics Co. Ltd

(Source: Samsung UK 2016)

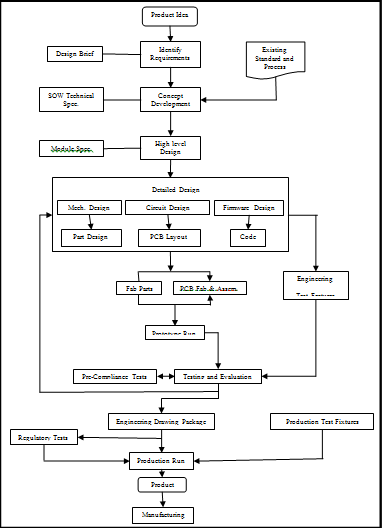

In order to perform manufacturing processes effectively and completing the entire development cycle for the electronics products, Samsung Electronics use several well-planned stages (Suh et al. 2016). These stages are arranged in such a fashion that the product development can be time and cost effective. The major stages used in Samsung Electronics are described below.

Conceptualization:

Samsung Electronics continuously attempt to formulate a new concept of products based on advanced technologies. It can be a new product or development of variances of the existing products in the market.

Research:

After developing the product concept, Samsung Electronics greatly emphasizes on the identification of suitable technology, vendors as well as methods for the production of the products (Lee et al. 2016).

Circuit Design:

Samsung Electronics uses several computers drafting software in order to develop a schematic diagram. In addition to that, the company also generates a preliminary parts list for prototyping as well as costing the product.

Samsung Electronics focuses on developing of attractive enclosure design as well as selection. After that, the company designs the outline of the printed circuits. The major steps for this stage are

- Selection of package style

- Design of graphics and nomenclature

- Resolving the requirements of printed circuit diagram

- Processing the printed circuit artwork on film

Developing Prototype:

Samsung Electronics develops a prototype product for the trial purpose. However, it is also noted that often hand-wired prototype products are used for the design process.

Design Review:

Samsung Electronics extensively focuses on evaluating the appearance, function, possible enhancements as well as build cost of the initial units as well as prototype products.

Test Setup:

In order to ensure the quality of the products Samsung Electronics places the apparatus, test procedures, detailed instruction of assembly as well as fixtures.

Documentation:

This stage is focused on providing the project's deliverables. This deliverable includes list of parts circuit diagram, parts sources, master printed circuit artwork, mechanical drawings, software source code as well as assembly drawings (Lee et al. 2013).

Agency Compliance:

According to the current law and regulation, Samsung Electronics requires several agency compliances.

Following Up:

Samsung Electronics actively review the supporting data of products, user response as well as experience of manufacturing facility. It is a major factor for improving the lower cost, value, and quality.

Figure 2: Process Map of Manufacturing in Samsung Electronics Co. Ltd

(Source: Lim et al. 2014)

Five operational performance of an organization is evaluated by the following factors,

- Quality

- Speed

- Dependability

- Flexibility

- Cost

Operational performance of Samsung is described below,

Five Operational Performance of Samsung

Quality: Samsung has standard optimization functions such as automatic neighbor relation, capacity coverage optimization and cell outage compensation. They also have unique features including drive test optimization; transmit power control and antenna tilt optimization. These features ensure a high quality operations management of Samsung. They also have smart scheduler that monitors all cells and centralizes radio resources management (Szeremeta 2013). This improves the pattern of allocation in order to maximize throughput.

Speed: Samsung’s network speed is excellent. Their operations and analytic tools are designed to monitor, manage and troubleshoot the network in real or near real-time. They have combined combine their smart SON and smart scheduler with cognitive analytics. In this way, their operators can load and allocate resources faster than any other organization. As a result, inefficiencies are reduced that helps to optimize their QoS and QoE (Szeremeta 2013).

Dependability: 3-bit MLC NAND flash technology of Samsung helps them to ensure reliability of their operations. Their Self-monitoring, analysis and reporting technology which is also known as SMART, helps to detect and report on various reliability indicators. Whenever a failure is estimated, the SMART technology warns the operators. Therefore, they can immediately replace the ailing drives that help to evade any type of data loss or unexpected outages (Yoon et al. 2016).

Flexibility: Samsung’s operations are highly flexible because of their superior supply chain management. Recently, the organization made seven changes in their supply chain operations that helped them to make their operations more flexible than before. Those changes are,

Samsung is all set to understand their customer behavior by sending employees to attend MBA programs at the local universities. At macro level, they collect preferences of the consumers. Those preferences are then incorporated into the product design through a method that is known as “Quality Function Deployment.”

Samsung is trying to enhance the internal operations using six-stigma model. They have adopted an approach called “DMAEV” that means define, measure, analyze, enable and verify (Szeremeta 2013).

Samsung has implemented APS system in that helps their operating team to develop a flexible production plan.

Management of Samsung is using a system called as “Voice of Business” that brings all the internal departments close to each other. As a result, they can easily establish an action plan based on collective decision.

Samsung has implemented merit-based system that has allowed the high performing employees to have a fast track career path (Lim 2016).

Samsung’s most of the components are manufactured in Korea that have helped them to achieve the economy of scale.

They have developed a very comprehensive risk management system. Their risk mitigation strategies are highly flexible.

Cost: Samsung’s advanced operation management allows the operators to automate their service operations. As a result, Samsung does not need a huge number of skilled human resources that reduces their overall operational expenses. Besides, their smart SON also helps them to reduce the need to carry out time-consuming and costly drive tests (Tyagi et al. 2015). Therefore, they can perform faster at a reduced cost.

Samsung has one of the most advanced operational management systems in their organization. Their operations not only reduce time and cost but also help them to provide superior services. Currently, they do not need any huge changes in their operations management, as everything is up to date and performing brilliantly. However, they can focus on their SMART technology that only handles mechanical problems. Samsung has no option to prevent erratic failures such as electrical surges. Therefore, they must implement something that can warn the operators about this type of issues. Besides, they can also establish strategic marketing based on diversity and different economic environments. The buying behavior and preferences of consumers are changing rapidly. Therefore, they should change their basic operation strategies and implement new design technologies and marketing strategies.

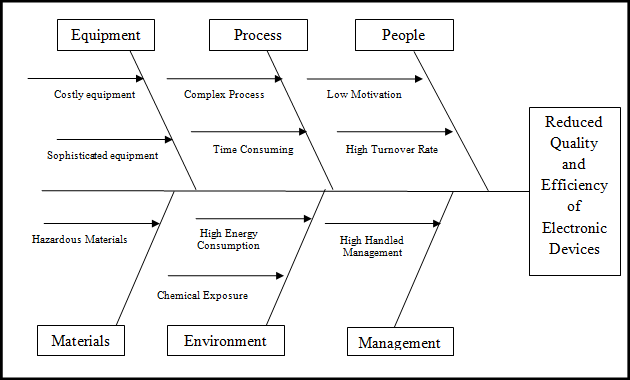

Process design and analysis is most effective for identifying various scopes for improving the manufacturing process. This kind of analysis is highly capable of point out different tangible benefits. Mostly these benefits are process efficiency, cost reduction as well as human resource allocation (Szeremeta 2013). There are several tools, which can be proved as imperative for analyzing the manufacturing process of Samsung Electronics. These tools are basically Fishbone Diagram as well as Pareto Chart.

Fishbone Diagram clearly indicates that, Samsung Electronics counter most of the problem in their manufacturing process. These areas are equipment, process, people, materials, environment as well as management. Samsung Electronics utilizes highly costly equipment for the manufacturing process. This situation raises a very crucial problem, as the machinery as well as the equipment cannot be replaced within a short notice (Hwang and Choung 2014). Henceforth, the damaged machines hinder the production growth of the electronics devices. At the same time, machines are noted to be quite sophisticated. As the machines perform a very delicate work in terms of producing or designing the circuit board, the machines are constructed numerous intricate parts. Therefore, it poses a greater possibility of damage to these sophisticated machines. These damaged machines or equipment reduce the production rate of Samsung Electronics' device at a whole.

In the same context, the nature of the manufacturing process itself presents a crucial issue for increasing the production rate. It has been perceived that the manufacturing process is highly complex and thereby it has to be conducted through effective planning and expertise. The complex process forces the company to carry through the manufacturing process in somewhat slow speed (Kumar and Veedu 2016). In addition to that, it increases the dependency on the experienced workforce. In this aspect, it can be evidently observed that the manufacturing process is a time-consuming process. Therefore, in order to produce a large number of electronic devices the company needs to invest in large numbers of machines.

Figure 3: Fishbone Diagram of Electronic Device in Samsung Electronics Co. Ltd

(Source: Card 2013)

As the fishbone diagram clearly indicated that the manufacturing process immensely depends on the experienced workforce along with a significant amount of investment, the company needed to hire an experienced workforce. However, the company faces a crucial problem in the context of hiring and maintaining the efficient labor force. Currently, the employees of the company are suffering from low motivation among the employees along with high turnover rate. In this situation, it can be easily optimized that the manufacturing process will be faltered due to the low support of experienced employees.

Moreover, the fishbone diagram effectively indicates that the management of Samsung Electronics does not focus on monitoring the manufacturing process in a critical manner. This distance from the actual manufacturing process damages the effective performance of the production system (Liu and Kim 2016). Furthermore, they cannot perceive the opportunities to increase the production rate as well. Henceforth, the rate of the production remains low due to this high-handed management. In addition to that, it reduces the flexibility as well as quick response system in the manufacturing process of Samsung Electronics.

Samsung Electronics experiences a greater problem in the context of environmental ground. Mainly, these environmental issues are high-energy consumption as well as chemical exposure to the employees. These factors drive the company towards the research activities to work on discovering the ways of reducing energy consumption along with chemical exposure (Yang et al. 2016). The battery of the electronic devices contains various chemical elements, which can cause effective damage to the work professionals. Samsung Electronics need to employ a superior technology and experienced workforce to contain as well as efficiently use these hazardous materials. Therefore, it is evident that manufacturing process highly depends on the greater investment as well as recruitment for increasing the production rate (Kovalev et al. 2013).

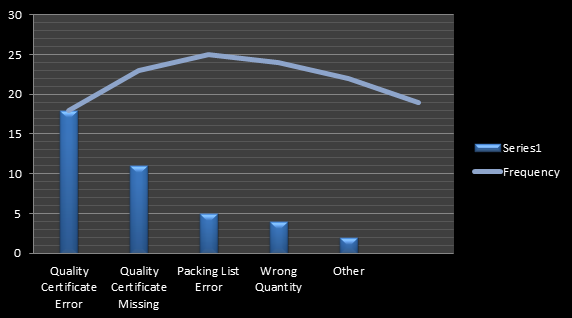

In addition to the fishbone diagram, the Pareto chart is also effective for identifying the level of disputes in the manufacturing process. The collected data of the dispute along with its range are depicted below.

|

Category |

Total (K) |

|

Quality Certificate Error |

18 |

|

Quality Certificate Missing |

11 |

|

Invoice Error |

6 |

|

Packing List Error |

5 |

|

Wrong Quantity |

4 |

|

Other |

2 |

Table 1: Document Complaints of Samsung Electronics Co. Ltd

(Source: Tyagi et al. 2015)

|

Category |

Frequency |

|

Quality Certificate Error |

18 |

|

Quality Certificate Missing |

23 |

|

Invoice Error |

25 |

|

Packing List Error |

24 |

|

Wrong Quantity |

22 |

|

Other |

19 |

Table 2: Document Complaints frequency of Samsung Electronics Co. Ltd

(Source: Tyagi et al. 2015)

Graph 1: Document Complaints of Samsung Electronics Co. Ltd

(Source: Tyagi et al. 2015)

The above-depicted Pareto chart effectively indicated that the quality of the electronic products had been deeply hindered due to these faults in the manufacturing process (Lee et al. 2016). Furthermore, the Pareto chart has also revealed that the manufacturing process of Samsung Electronics will be hindered in terms of its efficiency.

Samsung Electronics need a more effective planning of theactivities to improve the manufacturing process that will increase the production rate as well as quality and efficiency of the electronic products. These ways are described below:

- Employing a better leadership model:

Leaders with better leadership strategies should handle the manufacturing process of the organization. The management must understand every aspect of manufacturing process so that they can identify the strong as well as weak suits of the manufacturing process. This way the management will reduce the distance between ground level workers as well as the managers (Yoon et al. 2016). The workers can address their problems to the managers in a more efficient way. The managers need to work on eradicating those problems so that the employees can focus on increasing their production rate as well as quality of the electronic products.

- Initiating evaluated process plan:

Samsung Electronics need to develop an evaluated process plan, which will focus on every activity in a critical fashion (Hoover et al. 2016). This plan can be based on the previous process plan, albeit it must weigh up every activity in terms of the efficiency as well as relevance. This way the managers can monitor every nuance of the performance of the respective activities. Moreover, this particular plan will assist the employees to get a better guidance from the supervisor as they will be supervised more closely. In addition to that, the company will enhance the rate of the production, as they will be able to point out the shortcomings of the process plan (Tassey 2014). In addition to that, the carefully choreographed process plan will evidently reveal various opportunities to increase the production rate.

- Hiring experienced employees:

The above analysis has been immensely helpful to point out that the manufacturing process of electronic products in Samsung Electronics highly depends on the experienced employees (Yoon et al. 2016). However, it has also been revealed from the analysis that Samsung electronics suffers from a high turnover rate. Therefore, Samsung Electronics must hire numerous experienced writers in order to increase the speed of the production. In the same context, the experienced writers will be able to enhance the speed as well as efficiency of the electronics product (Lee et al. 2016).

- Increasing motivation:

The above-described article effectively disclosed that Samsung Electronics suffer from a low employee motivation along with the high turnover rate. Therefore, the management of Samsung Electronics must work on elevating the motivation of the employees (Lim et al. 2016). In this context, Samsung Electronics need to use the reward system for the good performance. The company also need to focus on increasing the opportunities for internal promotion so that the employees can be inclined to demonstrate their good performance. This way the production rate of the electronic products will be eventually increased.

Conclusion:

The above report has successfully addressed the background of Samsung Electronics. It has been revealed that Samsung Electronics is a business division of Samsung group operating its business in the electronics industry. It has also been found out that the first product of Samsung Electronics was a simple black-and-white television set. The paper has also been successful in the context of identifying various essential aspects of Samsung Electronics’ manufacturing process. It has been disclosed that there are several steps of manufacturing process, which play a significant role in producing the electronic products. These steps are conceptualization; research; circuit design; packaging and printed circuit layout; developing prototype; design review; test setup; documentation; agency compliance as well as following up.

The paper has been able to depict the mapping of entire manufacturing process in an efficient way. There are several tools of process design and analysis, which has been able to identify the severe problem of the manufacturing process. It has been disclosed that manufacturing process of Samsung Electronics experiences the problems in specific areas, which are equipment, process, people, materials, environment, and management. The major problem regarding the equipment is that the instrument and machines of the manufacturing are highly costly and sophisticate.

In addition, it has been observed that manufacturing process is itself complex and time-consuming. Moreover, the company suffers from low motivation and high turnover rate. In the same aspect, the company employs high-handed management that fails to perceive the criticality of the manufacturing process activities. The manufacturing process is hindered by the high-energy consumption as well as chemical exposure. Furthermore, it is also noted that the customers, as well as employees, are exposed to hazardous materials in this manufacturing process.

Reference List:

Card, A.J., 2013. A new tool for hazard analysis and force-field analysis: The Lovebug diagram. Clinical Risk, 19(4-5), pp.87-92.

Hoover, A.P., Ramesh, C. and Petermann, D.A., 2016. Method Of Resolving Multi-Patterned Color Conflicts For Multi-Row Logic Cells. U.S. Patent 20,160,147,929.

Hwang, H.R. and Choung, J.Y., 2014. The co-evolution of technology and institutions in the catch-up process: the case of the semiconductor industry in Korea and Taiwan. The Journal of Development Studies, 50(9), pp.1240-1260.

Kovalev, M.K., Kalinina, F., Androsov, D.A. and Cho, C., 2013. Synthesis of transparent and thermally stable polyimide-aramid nanocomposites–Prospective materials for high-temperature electronic manufacture applications. Polymer, 54(1), pp.127-133.

Kumar, A. and Veedu, V.P., 2016. Low cost semiconducting alloy nanoparticles ink and manufacturing process thereof. U.S. Patent 9,290,671.

Lee, D., Lee, B., Kim, S., Park, J., Lee, D. and Lee, C., 2016. Organic-Inorganic Composite Films And Methods Of Manufacturing The Same. U.S. Patent 20,160,103,233.

Lee, J., Shim, K., Chang, D. and Yang, W., 2016. Anode Active Material For Lithium Secondary Battery, Composition For Anode Including Same, And Lithium Secondary Battery. U.S. Patent 20,160,190,570.

Lee, J.H., Lee, J.H., Cho, H.I., Kim, D.K. and Ro, J.C., 2013. Method of manufacturing vertical gallium nitride based light emitting diode. U.S. Patent 8,361,816.

Lee, Y.S., Kang, T.H., Kwon, H.J., Kim, K.D., Kim, S.H., Mock, J., Lee, S.Y., Jung, M.S., Chun, H.M. and Hyun, J.W., 2016. Electronic Device And Method For Manufacturing The Same. U.S. Patent 20,160,044,801.

Lim, A.J., Village, J., Salustri, F.A. and Neumann, W.P., 2014. Process mapping as a tool for participative integration of human factors into work system design. European Journal of Industrial Engineering 6, 8(2), pp.273-290.

Lim, W.H., Kwak, T.S., Lee, H.S., Park, E.S., Kang, S.H., Kim, B.S., Kim, S.K., Park, S.M., Bae, J.H., Seo, J.W. and Jang, J.Y., 2016.Composition For Forming A Silica Based Layer, Method For Manufacturing Silica Based Layer, And Electronic Device Including The Silica Based Layer. U.S. Patent 20,160,177,133.

Liu, B. and Kim, S.M., 2016. Semiconductor Device Having A Fin Structure And Method Of Manufacture The Same. U.S. Patent 20,160,005,738.

Samsung UK. 2016. Samsung UK. [online] Available at: https://www.samsung.com/uk/home/ [Accessed 3 Aug. 2016].

Suh, S.K., Ko, D.K., Bulovic, V. and Bawendi, M., 2016. Quantum Dot Solar Cell Performance With A Metal Salt Treatment. U.S. Patent 20,160,035,919.

Szeremeta, W., 2013. Electronic display assembly comprising a display mount and a flex circuit wrapped around and adhered to the display mount. U.S. Patent 8,358,395.

Tassey, G., 2014. Competing in advanced manufacturing: The need for improved growth models and policies. The Journal of Economic Perspectives, 28(1), pp.27-48.

Tyagi, S., Choudhary, A., Cai, X. and Yang, K., 2015. Value stream mapping to reduce the lead-time of a product development process. International Journal of Production Economics, 160, pp.202-212.

Yang, J., Hwang, S., An, Y.K., Lee, K. and Sohn, H., 2016. Multi-spot laser lock-in thermography for real-time imaging of cracks in semiconductor chips during a manufacturing process. Journal of Materials Processing Technology, 229, pp.94-101.

Yoon, J., Noh, B., Lee, B. and Chun, H., 2016. Semiconductor Package And Method Of Manufacturing The Same. U.S. Patent 20,160,071,824.

Yoon, S., Park, S. and Shim, Y., 2016. Conductive Ink Composition, Conductor, And Electronic Device. U.S. Patent 20,160,032,126.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2017). Essay On Samsung Electronics' Manufacturing Process - Operations Management." (70 Characters). Retrieved from https://myassignmenthelp.com/free-samples/operations-management-manufacturing-process-of-samsung-electronics.

"Essay On Samsung Electronics' Manufacturing Process - Operations Management." (70 Characters)." My Assignment Help, 2017, https://myassignmenthelp.com/free-samples/operations-management-manufacturing-process-of-samsung-electronics.

My Assignment Help (2017) Essay On Samsung Electronics' Manufacturing Process - Operations Management." (70 Characters) [Online]. Available from: https://myassignmenthelp.com/free-samples/operations-management-manufacturing-process-of-samsung-electronics

[Accessed 15 February 2026].

My Assignment Help. 'Essay On Samsung Electronics' Manufacturing Process - Operations Management." (70 Characters)' (My Assignment Help, 2017) <https://myassignmenthelp.com/free-samples/operations-management-manufacturing-process-of-samsung-electronics> accessed 15 February 2026.

My Assignment Help. Essay On Samsung Electronics' Manufacturing Process - Operations Management." (70 Characters) [Internet]. My Assignment Help. 2017 [cited 15 February 2026]. Available from: https://myassignmenthelp.com/free-samples/operations-management-manufacturing-process-of-samsung-electronics.