IKEA's Supply Chain Management

Question:

Discuss aobut the Supply Chain Management of IKEA.

IKEA is a multinational group which was found in southern Sweden in 1943 by Ingvar Kamprad. The company has been the largest retailer of furniture in the world. The company is well known for its modern designs for different types of furniture and appliances and also for its interior designs as they are simple and eco-friendly. The firm is also known for its focus on cost control, ongoing development of the product, corporate power and the details of operations. In November 2017 the company has owned and controlled around 410 stores in 49 nations (IKEA Official Website, 2017).

The range of products is about 12,000 on the website of the company. The company is accountable for 1% of consumption of wood product which makes it one of the biggest consumers of product in the retail sector. The vision of the firm is to build a better daily life for a large number of people as possible and to help them to build their dream house at the reasonable cost possible (Fröding & Lawrence, 2017).

The herewith report analyses the effectiveness of four critical flows in supply chain management of IKEA and to evaluate its making process and supply chain forecasting techniques. In the end, the company is offered with some recommendation in the form of supply chain theories that can be applied to IKEA’s supply chain process.

IKEA has the biggest supply chain management in the world in terms of furniture products. Moreover, the company gives first priority to collaboration and coordination before conducting operations or activities. Thus, in case the policy does not match the organizational structure, it can create an adverse impact on the organization as a whole. Since, IKEA contains a flat structure in which they provide priorities to each employee (Stadtler, 2015). There is the presence of upper management in functions as well as locations to align the strategies with structures in order to run the supply chain management smoothly and efficiently.

The supply chain of IKEA is inclusive of a production flow. It encompasses raw material, production, distribution, suppliers and to the ultimate customer. Raw material development takes place in the initial sector in which IKEA designs and develops its product in Sweden. While the process of designing, IKEA do verification of that commodities whether they are meeting the requirements of customers.

Production Flow

IKEA is based on rare and exceptional products. It uses in-store logistics personnel so as to address stock management at store locations. Every in-store has a logistics manager who is liable for the ordering procedures and a product manager who is liable for material addressing logistics at each store of IKEA (Ntabe, et al, 2015). Once the product is selected and purchased by the customers, then they are required to head to the warehouse or store to assemble the product by themselves. As the product is picked up by the customer, IKEA has no need to employee labour that would otherwise assume such a responsibility. Thus, this assists in reducing labour costs for IKEA.

For conducting an effective distribution channel, IKEA makes the calculation of the exact quantity to do a production of the same in order to meet the demands of customers. It ensures minimum wastage of resources during production and warehousing. The company has a global distribution channel it can do delivery in large quantities and can make use of flat packages at a very reasonable cost. This can be considered as a feature of their distribution system as their mission is to provide right commodities at right time and place (Seuring, 2013). IKEA make a reduction in transportation costs by doing flat packaging. Further, large quantities can be packed easily and transported at a single time. In flat packaging, customers are required to assemble the transported product by themselves only. For IKEA, services of distributions play a role of the wholesaler. They help in protecting local space for storage plus dealing with the supplier on an international basis.

IKEA is said to be a leading retailer in terms of maintaining good relationships with suppliers. They make negotiation of prices with suppliers, checking quality measures and focusing on working and social environment. The code of conduct of IKEA is known as IWAY which stands for IKEA Way of Purchasing Home Furnishing Products. It is inclusive of minimum rules and regulations that further assist producers in reducing the effect of their operations on the environment to make it sustainable. The requirements present in IKEA lift up standards by conducting sustainable activities within the business and placing positive influence on the environment (Ellram and Cooper, 2014).

Figure 1 Flow of Goods, information and cash in IKEA

(Source: Brindley, 2017)

Another important role is played by consumers in the low-cost strategy of IKEA. As the customers are liable for retrieving the concerned commodity and accumulating it, IKEA gets benefits on this by saving labour costs, delivering and operating cost related to the assembling of furniture. IKEA manages the various key components of its value chain in an effective manner.

Distribution Channel

The IKEA company produce 10% of its products internally and rest it 90% products are being outsourced. This brings many benefits for the company like now it can focus more on the core functioning and also the less cost structure of company. The outsourcing helps managers of the company to direct their resources and energies towards the main activities which will bring more worth and competitive benefit (Brandenburg et.al, 2014).

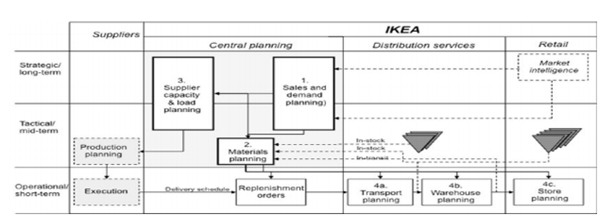

The company has built its centralised planning approach that has various stages. Firstly the emphasis was on the demand planning by implementing new software for it. Next the emphasis was on the enhancement of planning of materials by performing its first step which was the flow from supplier to direct channel by using new software. The company then extended its functions to cover the complete flow of supply from supplier to direct channels and then to end users.

The company has started creating worth from raw materials by coming in the process of manufacture after guaranteeing an eco-friendly low of supply of raw materials to the supplier by using either code of conduct or wheel evaluation. The company outlines its own items based on the demand of the market and with the given measure of raw material. In a situation when the variables are fixed the designer is responsible for maximizing the effectiveness and efficiency of the resources used in the manufacturing of the product (Mangan and Lalwani, 2016).

In the production area the company struggles to improve the efficiency of the production by consuming less amount of power and advanced standard of the environment. The company will also carry out an audit in production factories by visiting the suppliers on any occasion just to see whether they are working according to the code of conduct or not. It will also help in developing sustainable activities of business which will enforce a positive impact on both the environment and human.

As the production take place the products are then transported to the network of 47 owned distribution centres situated in 17 nations which are highly automated. To optimize the requirement of transportation and warehousing the finished goods are firmly packed in flat packages. This method of packaging makes it easy to transport and store finished goods easily (Wisner, Tan and Leong, 2014)

Figure 2 The global supply chain planning process of IKEA

(Source : Wisner, Tan and Leong, 2014)

Supplier Relationship

Though a uniform approach of the production does not mean that is it culturally insensitive. IKEA has placed great importance on the products so as to raise the taste and preferences of consumers globally. The company has about 50000 SKUs which will help in reducing the challenge of product variability. As learned in the course of TOM scattering out the demand of manufacture will allow the suppliers to have a constant cycle of time (Monczka and et.al, 2015). This will ultimately drive to lower cost of production per unit. Further using advanced scheduling and planning software will also help the company to assign the manufacturing to suppliers according to the capacity of production and availability of raw material with the supplier.

The SCOR that is the supply chain operation references model is a tool of management which is used to improve, communicate and address the supply chain management choices in the company and also with the customers and suppliers. The model explains the process of business which is required to satisfy the demands of customers (Stadtler, 2015).

Plan – spotting the requirement of production based on the demands and also determining the related cost and the required logistics.

Source – Placing the order of required raw material from the correct supplier.

Make – This involves efficient assigning of the resources for the activities of production and then producing the line of products with the required quality and quantity.

Deliver- the process of distribution is to deliver the finished products to the sales outlets, the storage units and the end consumers (Christopher, 2016).

Return - consumers are offered a warranty on the purchases made by them. If there is a fault in products or if they are not up to the required standard then consumers are liable to return the same and attain a replacement.

Enable - assembling all the members in the process of supply chain management by making them understand about the code of IWAY and by conducting uniform research to identify solutions for the problems and also including the employees the process of innovation (Lu and Swaminathan, 2015).

The company also relies on extensive spread forecasting and also generally plans about the production of five years in advance. The company also focuses on long-term plans so as to balance the production level around it manufactures.

There are numerous tools and methods of forecasting, essentially this can be divided into two categories first is qualitative and second is quantitative.

Global Supply Chain Planning Process

Qualitative techniques: This technique helps in basing the demands and needs of customers by taking their and experts opinions and perceptions into account. This type of technique is considered as a subjective method, the demand is particularly based on expert opinion, market research or by implementing Delphi method. This technique engages a jury of experts who make estimations concerning the demand where the aim is to reach a cohesive decision. Often, qualitative techniques are used in high-volume categories for a long-term period (Jonsson, Rudberg and Holmberg, 2013)

Quantitative method: this method relies upon quantitative models that make use of past data and information in order to forecast supply chain. The quantitative technique is also known as time-series components. By making use of this method, organizations comprise diversified components which are further influencing demand.

The major attribute which must be considered while selecting forecasting methods is cost, relevancy, time and ability to determine market and demand changes. The variation between both the techniques of forecasting is the degree of time and resources required to predict the demand and the most preferring method to analyze demand is the qualitative one (Rushton, 2014). Introduction of forecasting is used as a significant method of supply chain operating with assumptions of strategies. Retailers assemble information regarding demand and assess its impact on the supply chain as a whole. The use of forecasting tools will be helpful for IKEA in calculating future sales and supports in inventory and cash flow management adding to this, a business can set new plans for future growth.

Conclusion

After examining the supply chain of IKEA it can be concluded that it provides a wide variety of products to it end consumers. Also the demand for the items which the company presents is required maintaining a high level of quality standards in its operational activities and products. The market position of the group is high this is because of the global presence, a centralized chain of supply, customer oriented policies, strong relations with partners and suppliers, innovation and the strong brand image. Especially the sensible and practical plans included in the process of supply chain management have facilitated the company to obtain financial advantages and improve its competitive ability. This results that the company is fulfilling its objectives and is continue to expand its market position.

References

Brandenburg, M., Govindan, K., Sarkis, J. and Seuring, S. (2014). Quantitative models for sustainable supply chain management: Developments and directions. European Journal of Operational Research, 233(2), pp.299-312.

Brindley, C. ed., (2017). Supply chain risk. Taylor & Francis.

Christopher, M., 2016. Logistics & supply chain management. Pearson UK.

Ellram, L.M. and Cooper, M.C. (2014). Supply chain management: It's all about the journey, not the destination. Journal of Supply Chain Management, 50(1), pp.8-20.

Fröding, K., & Lawrence, G. (2017). Sustainability at IKEA. Linnaeus Eco-Tech, 67-77.

IKEA Official Website (2017), [Online] Available at <https://www.ikea.com/> (Accessed on 27 November, 2017)

Jacobs, R., & Chase, R. (2013). Operations and supply chain management. McGraw-Hill Higher Education.

Jonsson, P., Rudberg, M., & Holmberg, S. (2013). Centralised supply chain planning at IKEA. Supply Chain Management: An International Journal, 18(3), 337-350.

Lu, L.X. and Swaminathan, J.M. (2015). Supply chain management.

Mangan, J. and Lalwani, C. (2016). Global logistics and supply chain management. John Wiley & Sons.

Monczka, R.M., Handfield, R.B., Giunipero, L.C. and Patterson, J.L. (2015) Purchasing and supply chain management. Cengage Learning.

Ntabe, E. N., LeBel, L., Munson, A. D., & Santa-Eulalia, L. A. (2015). A systematic literature review of the supply chain operations reference (SCOR) model application with special attention to environmental issues. International Journal of Production Economics, 169, 310-332.

Rushton (2014) The Most Recognized Supply Chain Framework [Online]. Available at <https://www.apics.org/apics-for-business/products-and-services/apics-scc-frameworks/scor> (Accessed on 27 November,2017)

Seuring, S. (2013). A review of modelling approaches for sustainable supply chain management. Decision support systems, 54(4), pp.1513-1520.

Stadtler, H. (2015). Supply chain management: An overview. In Supply chain management and advanced planning (pp. 3-28). Springer Berlin Heidelberg.

Wisner, J.D., Tan, K.C. and Leong, G.K. (2014). Principles of supply chain management: A balanced approach. Cengage Learning.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2018). IKEAs Inventory Management: Optimizing Efficiency For Success. Retrieved from https://myassignmenthelp.com/free-samples/supply-chain-management-of-ikea.

"IKEAs Inventory Management: Optimizing Efficiency For Success." My Assignment Help, 2018, https://myassignmenthelp.com/free-samples/supply-chain-management-of-ikea.

My Assignment Help (2018) IKEAs Inventory Management: Optimizing Efficiency For Success [Online]. Available from: https://myassignmenthelp.com/free-samples/supply-chain-management-of-ikea

[Accessed 16 September 2025].

My Assignment Help. 'IKEAs Inventory Management: Optimizing Efficiency For Success' (My Assignment Help, 2018) <https://myassignmenthelp.com/free-samples/supply-chain-management-of-ikea> accessed 16 September 2025.

My Assignment Help. IKEAs Inventory Management: Optimizing Efficiency For Success [Internet]. My Assignment Help. 2018 [cited 16 September 2025]. Available from: https://myassignmenthelp.com/free-samples/supply-chain-management-of-ikea.