Discuss about the Supply Chain Management for Toyota Motor Corporation.

Toyota Motor Corporation is a Japan based company with it’s headquarter at Toyota Aichi. It is a Multinational company which has more than 3.5 lakhs employees all over the world and has ranked 13th in 2016 in terms of revenue. It is the first automotive company that produces more than 10 million vehicles in a year. The company was founded in 1937 by Kiichiro Toyoda and the most famous brands of Toyota are Lexux, Ranz, Scion and Hino. It is one of the largest multinational of the world.

The report discusses the supply chain management of Toyota. It explains the key flows in supply chain where in the effectiveness of the information flow, product flow, return flow and cash flow of Toyota is explained. The make process of Toyota is discussed where in the effectiveness of the production planning process and planning for material requirement are examined through the application of supply chain theories. Lastly, the forecasting models are reviewed and the most effective model is discussed for Toyota Company.

The key flows of supply chain refer to the product flow, information flow and money flow. The product flow indicates the flow from the starting of the product development, ie from the raw material to the end product that reaches the customer. The information flow states the flow of information in both directions from the customers and also from the suppliers (Ahi & Searcy, 2013). Money flow again refers to the flow of fund in both directions, from the consumer to the manufacturer and from the manufacturer to the supplier.

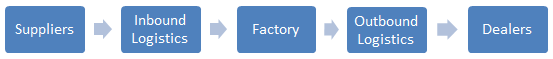

The product flow of Toyota can be briefed in the below flow chart

The flow in supply chain in an automotive firm is his complex due to the nature of the product. The parts are first produced by the suppliers and then send to the assembly plants through the inbound logistics (Barney,2012). The assembly plant is denoted as factory in the above flow chart where the vehicle is first brought in the body shop, then to the paint shop and then to assembly and finally to inspection. After the vehicle is produced, it is send to the outbound logistics through which it moves to the dealer point.

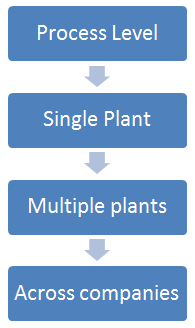

The information flow in Toyota is followed by value stream mapping that helps to track the flow of information and material across the development of product. The following flow chart explains the flow of the information

The Make Process

The flow chart explain the flow of information across the company to have quick responses to the customer requirements and to reduce the lead time between the order received from the customer to the delivery of the product to the customer. The processes are connected with continuous pull and flow of materials (Christopher, 2016). And the information flow is simplified by having a clear idea of the customer requirements on the time, volume, quantity and the production mix. The flow loop and the value stream in the company has to settle the time required for each task which need to be followed at all levels so that the company is able to spread the information across its employees and companies effectively

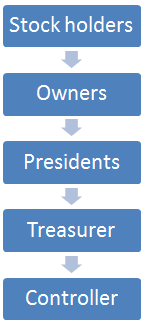

The money flow in the company is mainly from the stock holders. The flow is addressed in the flow chart.

The fund flows from the stock holders to board of directors, who are the owners of the company (Coyle et al.,2016). The fund is then allocated by the President to the Treasurer and controller who allocates and supervise the flow of money in the company.

In flow of money is properly organised in Toyota for having effective supply chain management. The transporters and the suppliers gets the payments on time and the product movement from the suppliers to the ultimate customer happens without any hindrance or shortage of fund flow required for meeting the required expenses (Seuring, 2013). The total flow of finance is controlled by the controller of finance and the treasurer is responsible for the maintaining the reserves.

The make process refers to the operational process that are executed periodically to ensure effective and efficient supply and logistic management. The major process in it are production planning and scheduling and material requirement planning process of Toyota company, so that ultimately the supply chain management is efficiently handled (Tayur, Ganeshan & Magazine, 2012).

The production scheduling of Toyota involves the method of dealing with monthly orders and based on the orders, the forecast is done for the future sales. Further a date for production is assigned to the vehicles and each vehicle is given a sequence. Basically Heijunka principle is used by the company to create a schedule for production that is spread across each day of each production month. Heijunka means smoothing in Japanese language and the production schedule is spread across the production month smoothly according to the weightage given to each parts of automobile. For example, production of engine is given more weghitage than body colour as if the production of engine gets affected then it has much more negative impact on manufacturing of automobiles than any other parts.

The Supply Chain Forecasting

Production scheduling involves setting up of production month that is different from the calendar month. Every calendar year has a production month and Toyota has assigned 52to 53 weeks for production in a year. Once the production plan is made, the scheduled production dates are sent to the dealers with the tentative build date of each vehicle. Based on these dates, the orders are taken by the consumers and a copy of the production schedule is sent to each assembly plants

The materials required for production are also planned accordingly. There are generally two different processes, one is for the local material requirement and other is for the overseas material requirement. The local materials are to be placed in the exact sequence which is required for the assembling of the parts to make the vehicle. It require exact calculation of time schedule when the parts ae to be assembled. Any mistake or missing the scheduled time for a second may lead to loss of production of several cars and affects the overall monthly volume of production. The overseas material requirement refers to making adjustment in production according to the shipping frequency and the size of the lot.

The key component of the production planning and material planning process are the setting up of standard work hours, and overtime hours. The standard work hours for every day is schedule to be 16 in Toyota Company and overtime is adjusted according to the condition of the operations in the plant. Another important component is Takt time which refers to the speed of the assembly line. Generally the takt time is 60 seconds which means the time taken by the vehicle to move from one station to another (Bozarth & Handfield, 2016). Any delay in this time, delays the production and affects the turnover of production in the company.

The other component is operations rate which means the percentage of time that the assembly line runs t the normal production rate. In Toyota plant, it is set at less than 100 percent (Brandenburg et al., 2014). The company give more importance to quality and so the workers are instructed to stop the assembly line if any problem occurs. The operation rate reduces by the amount of time taken for correcting the vehicle.

The vehicle per hour and vehicle per day are also the component of the planning process which calculates the total work hour. The model ratio and model volume calculates the ratio of production for a particular model.

The supply chain forecasting is done by the organization to keep the pace of growth in the industry and maintain competitive position against the rival firms. However, the forecasting and anticipatory supply chain varies across the sectors and companies (Fawcett, Ellram & Ogden, 2014). However, there are few principles that should be followed to develop a supply chain forecasting. The principles are regionalization, new kinds of talent and tighter connections with strategies.

The multinational corporations try to develop effective supply chain system in every region where they move in. Adoption of local supply chain system and moulding their system according to the local requirement refers to regionalization of the supply chain management system. In today’s era of globalization, it is important to obtain the regional adoptability skills by the managers to succeed his company in the foreign market (Monczka et al., 2015).

The two most famous supply chain forecasting methods are optimization and simulation techniques. In optimization which is base on a mixed integer program, forecast demand so that the plans for the production, inventory and transportation can be drawn, based on which the supply chain cost can be minimised. The other method of forecasting is simulation techniques which help to execute management plans on regular basis by using the demand history over a four year period.

There have been several centres in the world where the cost of production is very low, the multinationals take advantage of this and shift their production to this place. Such regionalization of production requires proper supply chain management of the product by the company (Schönsleben,2016).The optimization techniques helps in deriving the advantages from such centres.

The markets where the inputs are not available at low cost, the company tries to localize the supply network so that the cost of production reduces (Stadtler, 2015). The company need to forecast the supply chain management of such market effectively so that there is no delay in the supply of the goods. The simulation technique can be used for effective results

In the past supply chain management was not considered as apart of the strategy but gradually Toyota executives and CEO realized the importance of supply chain management and it became an important part of strategies for effective return of the company. The proactive actions on supply chain system help the company to solve the trivial issues and increase the efficiency of the production of organization.

The forecasting of supply chain management requires a different kind of talent with integrate background that could combine the global experience with creative problem solving and analytical skills (Christopher,2016). It requires true innovations and many companies have started giving importance to the forecasting of supply chain management and recognized its importance in the future

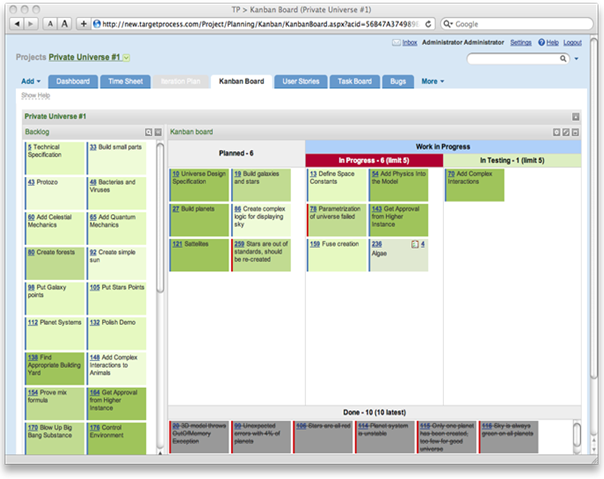

Toyota has developed a Kanban system to handle the supply chain management effectively. It helps in maintaining inventories by sending visual signals for delivery of new shipment and production. The signals are tracked through replacement cycles and help the suppliers and buyers in understanding the requirements (Wisner,Tan & Leong, 2014). The development of Kanban system was done to understand the operations of super markets in United States. It has used the demand rate of the market to control the production rate by passing the demand from the customer to producer through the supply chain system. This approach is called as the pull system where the supply and production of goods is determined by the consumer demand.

Traditionally Kanban cards were used to notify the suppliers. Now it has been replaced by electronic system where the signals are sent automatically to the suppliers once the customers consume the resources. It has been implemented in Enterprise Resource Planning System such as Microsoft Dynamics and SAP ERP

Figure1: The Kanban Sysiem in SAP ERP

(Source: Waters & Rinsler, 2014)

The figure shows the Kanban system in SP ERP used to track the shortage of supply and to link the demand directly with the production and supply of the good.

Conclusion

The paper explains the supply chain management system of Toyota Motor Corporation. It explains the key flows in supply chain, the make process of Toyota and the forecasting models of Toyota Company.

The method of supply chain used by the company is good and meets the requirement of the company. However, in international market to compete against the local firm, the company needs to upgrade its supply chain management effectively by applying advance level of Enterprise Resource Planning system. The simulation technique is suggested here as it helps in deriving expected returns on daily basis. Further, the company need to train their workers on regular basis to reduce the loss of production due to poor time management during the assembling of the product. The management of time and the prompt response to the problem during assembling is very vital and company can achieve it only by vigorous training of the employees. Under the situation, if the daily basis expected report is available, as in Simulation technique, the company can overcome the shortages effectively.

References

Ahi, P., & Searcy, C. (2013). A comparative literature analysis of definitions for green and sustainable supply chain management. Journal of Cleaner Production, 52, 329-341.

Barney, J. B. (2012). Purchasing, supply chain management and sustained competitive advantage: The relevance of resourceâ€Âbased theory. Journal of Supply Chain Management, 48(2), 3-6.

Bozarth, C. B., & Handfield, R. B. (2016). Introduction to operations and supply chain management. Pearson Higher Ed.

Brandenburg, M., Govindan, K., Sarkis, J., & Seuring, S. (2014). Quantitative models for sustainable supply chain management: Developments and directions. European Journal of Operational Research,233(2), 299-312.

Christopher, M. (2016). Logistics & supply chain management. Pearson Higher Ed.

Coyle, J. J., Langley, C. J., Novack, R. A., & Gibson, B. (2016). Supply chain management: a logistics perspective. Nelson Education.

Fawcett, S. E., Ellram, L., & Ogden, J. A. (2014). Supply Chain Management: From Vision to ImplementationAn Integrative Approach. Pearson Higher Ed.

Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2015). Purchasing and supply chain management. Cengage Learning.

Schönsleben, P. (2016). Integral logistics management: Operations and supply chain management within and across companies. CRC Press.

Seuring, S. (2013). A review of modeling approaches for sustainable supply chain management. Decision support systems, 54(4), 1513-1520.

Stadtler, H. (2015). Supply chain management: An overview. In Supply chain management and advanced planning (pp. 3-28). Springer Berlin Heidelberg.

Tayur, S., Ganeshan, R., & Magazine, M. (Eds.). (2012). Quantitative models for supply chain management (Vol. 17). Springer Science & Business Media.

TOYOTA MOTOR CORPORATION GLOBAL WEBSITE. (2009). TOYOTA MOTOR CORPORATION GLOBAL WEBSITE. Retrieved 29 July 2016, from https://www.toyota-global.com/

Waters, D., & Rinsler, S. (2014). Global logistics: New directions in supply chain management. Kogan Page Publishers.

Wisner, J. D., Tan, K. C., & Leong, G. K. (2014). Principles of supply chain management: a balanced approach. Cengage Learning.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2017). Supply Chain Management Essay For Toyota Motor Corporation.. Retrieved from https://myassignmenthelp.com/free-samples/supply-chain-management-toyota-motor-corporation.

"Supply Chain Management Essay For Toyota Motor Corporation.." My Assignment Help, 2017, https://myassignmenthelp.com/free-samples/supply-chain-management-toyota-motor-corporation.

My Assignment Help (2017) Supply Chain Management Essay For Toyota Motor Corporation. [Online]. Available from: https://myassignmenthelp.com/free-samples/supply-chain-management-toyota-motor-corporation

[Accessed 01 June 2025].

My Assignment Help. 'Supply Chain Management Essay For Toyota Motor Corporation.' (My Assignment Help, 2017) <https://myassignmenthelp.com/free-samples/supply-chain-management-toyota-motor-corporation> accessed 01 June 2025.

My Assignment Help. Supply Chain Management Essay For Toyota Motor Corporation. [Internet]. My Assignment Help. 2017 [cited 01 June 2025]. Available from: https://myassignmenthelp.com/free-samples/supply-chain-management-toyota-motor-corporation.