Types of Fibers for Concrete Reinforcement

Question:

Discuss about the Behavior Of Plastic Fibers In Concrete.

Various fields including science and construction industry have been greatly attracted by the Use of plastic fibers to strengthen concrete as compared to other types of steel. This paper has analytically presented the present state of information and technology of adopting plastic fibers to reinforce concrete. A detailed review of the effects of plastic fibers on the fresh and hardened concrete properties have also been covered in this paper (Ozel, 2009, p. 552).

Among the many reasons for the occurrence of cracks, ion concrete elements are the deformation as a result of shrinkage. The concrete elements vary ranging from pavements, overlays and even slabs. Polypropylene fibers in most cases help to improve the cement based composites which are more vulnerable to shrinkage. The deformations may be caused by very many factors such as restrained shrinkage, autogenously and also increased composite resistance.

In the first 12 hours of concrete shrinkage, the plastic fibers reduce and lessen the presence of cracks by harnessing the strength and capacity of the cement paste (Mertz, 2008, p. 844).

When these cracks are not controlled, the small tiny cracks formed due to the drying shrinkage results in the growth of larger cracks. The fibers also help in reducing the width of the cracks thereby preventing harmful substances from the environment from penetrating. Generally, the control of cracks is vital for the advancement of more durable and long-lasting structures.

Literature review

Fiber Reinforced Concrete that contains a tough material enhances the structural integrity of the concrete due to the uniformly distributed fibers. There are two Types of Fibers which include the;

- Steel Fibers

- Synthetic Fibers- this includes the plastic fibers.

These Fibers are primarily used in concrete for the below purposes;

- For the prevention of cracking which forms as a result of both drying and plastic shrinkage (béton, 2007, p. 322).

- Besides, the fibers help to enhance the robustness of the concrete.

- Fibers also help to limit the penetrability of the concrete and thereby lessening water leakage during construction.

Advantages of Fiber

Polypropylene and Nylon Fibers –these type of fibers are mostly applied due to their property of improving the mixing cohesion and also the ability to pump over longer distances. They also exhibit the property of increasing the resistance that results from freeze-thaw or explosive palling during incidents of severe fire .for this reason, these fibers have been internationally recommended since apart from offering protection to the concrete it also helps to protect lives and property (Hensher, 2016, p. 985).

Steel Fibers- these type of fibers also are advantageous in terms of Improving the structural strength of concrete and Reducing the size of the cracks by firmly holding and in turn promoting its durability •nevertheless, steel fibers Improves abrasion resistance and freeze-thaw resistance (Paramanantham, 2015, p. 548)

Effects of Plastic Fibers on Concrete Properties

Role of fibers

The process of crack formation in concrete elements plays a key role since it constantly exposes the structures to a high risk of corrosion. Theses crack lower the quality of the concrete, therefore, affecting their durability and also their aesthetic value. Hence there is a need to minimize the size of these cracks and more particularly this is achieved with the addition of plastic fibers. There are various reasons behind the formation of these cracks including;

Fire damage, plastic shrinkage, freeze-thaw damage and also plastic settlement as discussed below.

Plastic shrinkage

These stakes place when the water present at the surface evaporates prior to the bleeding water reaching the surface. The addition of the plastic fibers will help minimize the extent of the shrinkage crack due to their property of flexibility and also ability to fit into form (Pielert, 2011, p. 646).

Plastic settlement

This occurs when there is a high rate of bleeding and the presence of some resistance when settling. The plastic fiber when added will help to fix this problem since they are uniformly distributed and flexible thereby ionizing the resistance experienced (A.E. Naaman, 2014, p. 993).

Freeze-thaw damage

The addition of plastic fibers in concrete helps to limit the flow of water by inhibiting the flow of water through the small nodes. This implies that there will be an improvement in cement hydration and also a reduction of the water flow or leakage which results in the cracking (R.N. Swamy, 2015, p. 763).

Fire damage

The presence of heat or fire creates penetrative ways into the concrete thereby disporting the moisture which is present on the outer layer. These moisture vapors get back into the cold interior parts and get reabsorbed. These vapours when accumulates increases the pressure rapidly and eventually results into palling and concrete racks. The addition of plastic fibers releases the vapor pressure into new voids thus reducing the extent of spalling (Antonio Nanni, 2014, p. 420).

Properties of Plastic Fiber Reinforced Concrete

Prior to the mixing of concrete, certain variables that are adjusted to inhibit the fibers from balling. These variables may include the fiber length, amount and design mix variables. Best mixes typically will comprise of an increased volume of mortar as matched to the conventional concrete mixes which are normally restricted between 100 and 200 to minimize difficulties that may arise during construction. Conventionally, plastic fibers are randomly and uniformly distributed in the concrete; nonetheless, to obtain greater strengths the concrete is placed such that the fibers get lined up in the direction of applied stress

Properties of Plastic Fibers

Below are some of the properties of the plastic fibers

These fibers are applied in two ways i.e.

These fibers are applied in two ways i.e.

In thin sheet components where they provide the primary reinforcement and the volume content of fiber is comparatively high such that it exceeds 5% purposefully to attain both solidification and strengthening (Yin, 2017, p. 777).

The other way of applications is when the volume content is relatively low such that it less than 0.3% thereby providing the secondary reinforcement for specifically for crack control,

Effects of plastic fibers on concrete

Plastic fibers have various influences on both fresh and hardened concrete as discussed below

Effects on Fresh Concrete

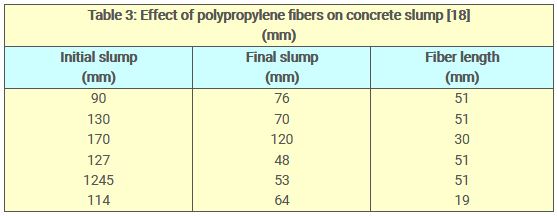

The workability of fresh concrete is normally determined by a parameter known as the slump test. The value of the slump is influenced by the content of water and its absorption properties. Also, it is attributed to the texture, shape and the surface characteristics of the components forming the mixture. The addition of the plastic fibers to the concrete decreases these value slowly. Thereby resulting in an increase in the bond and cohesiveness of fresh concrete.

The plastic fibers shear apart during the mixing of the components thus creating an interconnection of the individual fibers and the fiber filaments. As a result of the large surface area, the fibers mechanically anchor to the cement paste (Clarke, 2009, p. 877).

This mixture has a reduced rate of bleeding and aggregate settlement due to the firm holding of the concrete by the plastic fibers. As a result of the high tensile strength of the plastic fibers, early plastic shrinkage cracking is greatly managed by improving the tensile capacity of plain concrete to provide resistance to the tensile stresses initiated by the typical volume changes.

Moreover, the fibers uniformly distribute these tensile tensions all over the concrete and with the decrease in plastic shrinkage cracking, concrete cracks get reduced. In the event that shrinkage cracks get formed, they get managed by the plastic fibers which reduce their size and width (James Shackelford, 2007, p. 542).

Below is a table of the effect of the plastic fibers

Effects on Hardened Concrete.

Plastic fibers do not have a significantly greater effect on the compressive strength or elastic modulus but only on the tensile strength. As discussed below, the Addition of plastic fibers intensifies the splitting of the tensile strength by approximately 30% to 60%.

Compressive strength

This is a vital factor in concrete since it determines other parameters such as the tension and flexure among others. It is realized that the addition of plastic fibers will either reduce or increases the compressive strength of concrete through the overall effect is always negligible.

Limitations of Plastic Fibers in Concrete Reinforcement

Flexural tensile strength: it is observed that with an increase in the amount of the added plastic fiber, the tensile strength increases (AL-GHAMDY, 2012, p. 763).

Bond strength:

Typically, the bond between the matrix and the fiber should be desirable and upon attaining the strengthening critical fiber volume, multiple racking then gets easier to achieve. These multiple cracks when loosely spaced reduces the possibility of harmful substances from penetrating. The plastic fibers offer High bond strength that helps to provide close crack spacing (Singh, 2016, p. 552).

Fracture Properties: the addition of fibers improves the failure behavior of high-strength concrete.

Creep and shrinkage properties:

Fibers help to minimize the creep strain rate and also concrete shrinkage that is caused by the removal of water from concrete during drying. Since the fibers do not shrink, they will be able to delay the process of shrinkage thereby overall reducing the deformation (Jochen Bundschuh, 2010, p. 998).

Chloride penetration:

Apart from the improved mechanical properties, the addition of plastic fibers also reduces the possibility of penetration by chemical substances such as chloride since the interfacial transition zone in the direction perpendicular is blocked (Baoguo Han, 2017, p. 620).

Obstacles in Use of Plastic fibers

Despite the use of plastic fibers gaining popularity, there is still need to do some improvements. Of significant note is the poor bond provided by some plastic fibers which provide a reduced pull-out strength. Incidents of fire also may result in cracking of greater porosity. The plastic fibers are also prone to destruction when exposing to too much sunlight and oxygen since they do not have a well-designed protection system. Further, due to reduced elasticity as compared to the cement matrix, the fibers sometimes acts as an initiator of the small cracks thus creating more pores in the cement elements (Berga, 2011, p. 531).

Evaluation Analysis

The recent design and construction of new buildings have taken into recognition the use of plastic fibers for the purposes of controlling shrinkage cracking and deformation. The application of these fibers is recommended for concrete structures as a result of the improved performances and effective cost-benefit ratio. Below are some of the advantages that make the plastic fibers recommendable for use in concrete structures (Mindess, 2014, p. 332).

- Plastic fibers are compact and easy to pump and place,

- Plastic fibers provides a safer working environment

- Plastic fibers also limit the rebound effect by improving the strength of wet concrete.

- Since the plastic fibers are entirely synthetic, chances of corrosion are greatly reduced.

- Plastic fibers also show enhanced impact resistance when compared to conventionally reinforce brittle concrete(Gustavo J. Parra-Montesinos, 2012, p. 542).

- Besides, plastic fibers improves the abrasive resistance in concrete floors by regulating the bleeding during the early stages of concrete cracking

- Also, plastic fibers increase the tensile strength and impact resistance thereby providing a reduction in the weight and thickness of structural components(Ying-shu Yuan, 2015, p. 833).

Conclusion

In conclusion, the research was based on the determination of the behavior of plastic fiber on concrete. It has been noted that plastic fibers offer the best reinforcement to concrete as compared to other reinforcement fibers. Below were some of the reason that demonstrated the best characteristics of plastic fibers in the prevention of crack formations in concrete elements.

When concrete is reinforced with plastic fiber, there is improved cohesion in the mixture and also the ability to pump over longer distances. Cases of fire breakouts also are countered by offering a stronger resistance to the explosive spalling. Besides, apart from improved structural strength and ductility of the mixture, plastic fiber offers a high resistance to the shrinkage during. The research also indicates that plastic fibers help to improve the resistance to freezing thaw and abrasion.

The above properties ensure that the width of the crack formed in the concrete material is greatly reduced thereby improving the lifespan and the aesthetic value of the concrete.

References

A.E. Naaman, H. R., 2014. High-Performance Fiber Reinforced Cement Composites 2. 5th ed. Chicago: CRC Press.

AL-GHAMDY, D. O., 2012. EFFECT OF MATRIX COMPOSITION ON STEEL FIBER REINFORCED CONCRETE PROPERTIES. 3rd ed. Chicago: University of MICHIGAN,

Antonio Nanni, A. D. L. H. J. Z., 2014. Reinforced Concrete with FRP Bars: Mechanics and Design. 3rd ed. Carlisle: CRC Press.

Baoguo Han, L. Z. J. O., 2017. Smart and Multifunctional Concrete Towards Sustainable Infrastructures. 5th ed. Westminster: Springer,

Berga, L., 2011. Dams and Reservoirs, Societies and Environment in the 21st Century. 3rd ed. Chicago: Taylor & Francis,.

béton, f. F. i. d., 2007. FRP Reinforcement in RC Structures. 4th ed. new york: fib Fédération Internationale du béton.

Clarke, J., 2009. Alternative Materials for the Reinforcement and Prestressing of Concrete. 4th ed. Westminster: CRC Press,

Gustavo J. Parra-Montesinos, H. W. R., 2012. High-Performance Fiber Reinforced Cement Composites. 2nd ed. Chicago: Springer Science & Business Media.

Hensher, D. A., 2016. Fiber-Reinforced-Plastic (FRP) Reinforcement for Concrete Structures:. 3rd ed. Carlisle: Elsevier,

James Shackelford, R. H. D., 2007. Ceramic and Glass Materials: Structure, Properties and Processing. 2nd ed. Carlisle: Springer Science & Business Media.

Jochen Bundschuh, M. C. S. A., 2010. Introduction to the Numerical Modeling of Groundwater and Geothermal Systems: Fundamentals of Mass, Energy and Solute Transport in Poroelastic Rocks. 3rd ed. Westminster: CRC Press.

Mertz, D. R., 2008. Application of Fiber Reinforced Polymer Composites to the Highway Infrastructure, 2nd ed. new york Transportation Research Board.

Mindess, S., 2014. Developments in the Formulation and Reinforcement of Concrete. 5th ed. new york Elsevier.

Ozel, M., 2009. The behaviour of concrete beams reinforced with 3-D fibre reinforced plastic grids. 2nd ed. Chicago: University of Wisconsin--Madison,

Paramanantham, N. S., 2015. Investigation of the Behavior of Concrete Columns Reinforced with Fiber Reinforced Plastic Rebars. 2nd ed. Westminster: Lamar University.

Pielert, J. H., 2011. The significance of Tests and Properties of Concrete and Concrete-making Materials. 2nd ed. Chicago: ASTM International,.

R.N. Swamy, B. B., 2015. Fibre Reinforced Cement and Concretes: Recent Developments. 3rd ed. Westminister: CRC Press,

Singh, H., 2016. Steel Fiber Reinforced Concrete: Behavior, Modelling and Design. 3rd ed. Melbourne: Springer.

Singh, H., 2016. Steel Fiber Reinforced Concrete: Behavior, Modelling and Design. 2nd ed. Carlisle: Springer.

Ying-Shu Yuan, S. P. S. H.-l. L., 2015. PRO 32: International Conference on Advances in Concrete and Structures. 5th ed. new york RILEM Publications.

Yin, S., 2017. Development of Recycled Polypropylene Plastic Fibres to Reinforce Concrete. 2nd ed. Chicago: Springer.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2019). Plastic Fibers For Concrete Reinforcement: Properties And Effects. Retrieved from https://myassignmenthelp.com/free-samples/behavior-of-plastic-fibers-in-concrete.

"Plastic Fibers For Concrete Reinforcement: Properties And Effects." My Assignment Help, 2019, https://myassignmenthelp.com/free-samples/behavior-of-plastic-fibers-in-concrete.

My Assignment Help (2019) Plastic Fibers For Concrete Reinforcement: Properties And Effects [Online]. Available from: https://myassignmenthelp.com/free-samples/behavior-of-plastic-fibers-in-concrete

[Accessed 25 May 2025].

My Assignment Help. 'Plastic Fibers For Concrete Reinforcement: Properties And Effects' (My Assignment Help, 2019) <https://myassignmenthelp.com/free-samples/behavior-of-plastic-fibers-in-concrete> accessed 25 May 2025.

My Assignment Help. Plastic Fibers For Concrete Reinforcement: Properties And Effects [Internet]. My Assignment Help. 2019 [cited 25 May 2025]. Available from: https://myassignmenthelp.com/free-samples/behavior-of-plastic-fibers-in-concrete.