Purchasing Management and Supplier Selection Criteria

Question:

Write a report about the purchasing management.

The purpose of this report is to show the various aspects of the purchasing management with focus on the supplier selection criteria and an extended emphasis on the impact of supply chain of a company with the use of Internet communication Technology (ICT). For the purpose of supplier selection it has been defined whether single sourcing or multiple sourcing is appropriate for the selected company. The associated purchasing cost related to the various equipments has also been determined. The purchasing portfolio management has been prespared on the basis of Peter Karlijic model. The analysis shows the various types of leverage items, strategic items, non-critical items and bottleneck items which are directly influencing the purchasing activities of a company. The final of the report also suggests the rationale for selecting activity based costing versus total cost ownership (Monczka et al., 2015).

The company selected for the purpose of study is Toyota Motor Corporation. The company was started in the year 1936. The basic model of the car started with production of AA model of cars. The leading Japanese carmaker id known for being one of the 13th largest companies on the world in terms of revenue and it had earned itself a reputation of producing more than ten million car models in a very short span of 12 years. The main competition is faced by companies such as General Motors, Ford, Honda and Volkswagen. Toyota has a reputation of application of lean manufacturing system into its entire production of the materials. The main supply of the company is controlled through tier 1 and tier 2 suppliers. The tier 1 suppliers are responsible for providing the primary part of the cars such as chassis and engines. The tier 2 includes the suppliers are responsible for supplying of those materials which are required for the required for the purpose of assembling (Hines, 2015).

The multiple sourcing criteria of the company involve the participation of both tier and tier 2 suppliers. As it has been discussed previously that tier 1 supplier are responsible for supplying of the primary car parts such as engines and chassis and the tier 2 suppliers engage in providing the parts such as crankshaft, spark plugs, valve and sump. These parts are necessary to furnish the tier 1 parts of the car. The Toyota Engineering and Manufacturing North America is one of the most prominent suppliers of the company. The suppliers focus on getting the purchasing policies and the gui9delines provided in the policies help the suppliers to know about the basic principles of purchasing ion North America, assisting the suppliers to increase the competitiveness in the auto manufacturing industry and engaging in long term relationship. The long-term relationship is maintained through annual purchasing policy and supplier support system. (Welcome to ToyotaSupplier.com, 2016).

According to Verma (2014), the rationale for the selection of the suppliers is based on the following criteria:

- Importance of the new suppliers: The process of identification of the suppliers should involve the evaluation cost effectiveness than the existing suppliers. The recognition of the new suppliers should be based on the reasons based on the buyers and internal customers for procurement of the products.

- Qualification screening process: The supplier has to qualify through various types of tests such as delivery performance, contracts terms, and resolving of the various problems. The financial status also needs to be checked based not the supplier rating. The availability of the surge capacity also influencer the selection criteria of the suppliers.

- Quality: The needs to adhere to various types of quality aspects such as ISO 9000 certification and similar. In case of any discrepancy related to quality issue the supplier’s organization needs to verify thoroughly.

- Information requests to suppliers: After the identification of the suppliers the request for information helps in identifying the buyers need and buyer also gain the knowledge about the types of the products which a supplier can provide. The request for proposal consists of the performance requirements details, which describes the potential strength and flexibility to understand the composition of particular material.

- Contract terms: The contract term states how a buyer will pay to the suppliers, the choice of a particular contract term may be long term, short term, fixed cost and cost plus basis. The payment terms in the contract specifies about the various form of contractual obligations. The payment of the various parts of the car can have fixed price, which states that the supplier will be paid irrespective of the actual cost of execution of the contractual agreements. In case of cost plus agreement the criteria for payment can be based on a certain fixed percentage and total cost incurred.

- Selection of the suppliers: Based on the supplier rating and contract terms, the appropriate suppliers need to be selected who can provide take and orders and meet the delivery within the required set of time.

- Supplier monitoring: The surveillance of the various activities of the suppliers can range from weeks to years. The monitoring criteria have several aims such as ensuring higher quality, accurate conformity of the specifications and monitoring for the purpose of cist containment.

In several cases while selection of the supplier based on the quality it has been observed that certification documents are misleading and tampered. This adds to the complexity of the buyers in assessing the capabilities of the supplier. These further raises the need to check the materials based on the specifications and when the buyers act on behalf of internal customers.

Case Study: Toyota Motor Corporation

The negotiation process to between the buyers and supplier often act as a major hurdle in the selection of the supplier and buyer, the main problem arises when the company attempts to induce the favorable terms to the suppliers and in similar way the supplier attempts to induce the price from the buyers. This leads to one sided benefit and paves the way for numerous conflicts in the future (Jahani et al., 2015).

The Karljic model for purchasing helps to analyze the purchasing portfolio of a company. This particular model shows the working methods of the purchasing department. The two main dimensions of the portfolio focuses on the profit impact based on the strategic importance of the materials and risks related to supply of the materials. The supply risk is mainly associated to the abundance or scarcity of the materials and to what extent the materials are up to date in terms of technological innovations and requirements of substitution (Knight & Preston, 2014).

Figure 1: Karljic Purchasing Portfolio

(Source: Artzblog.com, 2016)

Some of the most noted initiatives by the company include the incorporation of data communication module in the broader range of vehicles. The changes are due to be implemented from the year 2017. The net result of this facility will connect the cars of the Toyota with cellular telecommunications networks, which will further expand the opportunity for the ability to transmit information for various types of products and services. The purchasing manager of the company is responsible for assuring the quality aspect of the company (Information Technology for Toyota_Motor (TM), 2016)

The main purchasing goal and suggestion for improvement has been shown below as follows:

|

Analysis of purchasing Goals |

Recommendations |

|

Providing safe, reliable and economic mode of transportation. |

Use of industrial robots for the purpose of manufacturing of the cars. This will automate the process of lifting of heavy items from place to place. Assembling of the parts, joining and paint job. The industrial robots ensure high level of safety thereby by reducing the labor cost to a significant amount (Mori et al., 2012). |

|

Addressing customer concerns and innovating in terms of reinventing through sufficient information disclosure. |

Improving the customer satisfaction level by addressing to the customer enquiries through websites, blogs and emails. |

|

Holistic view of development by contributing to the local communities with an open stance towards the new suppliers and focusing on growth based on mutually beneficial business dealings with the distributors and the suppliers. |

Promotion of local purchasing in e-newspapers, blogs and other forms of electronic media. This can be also achieved by establishing sales network through vendor sourcing and enterprise resource planning. |

|

Development of environmental friendly vehicles and technologies for continuous improvement of the same. |

Use internal combustion engine and introduction electric motors in the car models will enable the company to produce hybrid models of cars. The technology of ethanol car by using renewable fuel will significantly improve the environmental aspect of the cars (Klöckner et al., 2013). |

|

Reducing the no. of defect related to the accelerators of the car, also ensuring the reduction in the error rate in the manufacturing process. |

In order to ensure this goal the company needs to incorporate six- sigma and automate the process of error detection. |

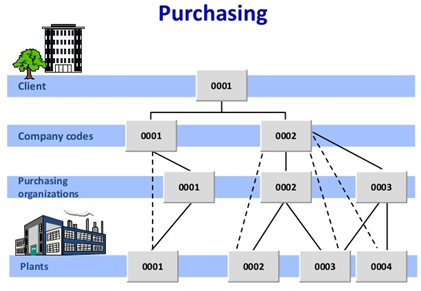

The main focus of the internet communications technology is seen in integration of the core functional areas with the enterprise resource planning through software systems. The purchasing is a four stage process in Toyota Motor Corporations. Unique codes are assigned to clients, purchasing organizations and plants. This shows the flow of purchasing decisions among all the levels of the organization. The changes in the inventory and procurement activity are updated real time through this software. The purchasing operations are manages seamlessly with the help of ERP software. (SAP, Toyota InfoTechnology Center and VeriFone Connect Cars and Provide Drivers With Simplified Fueling. 2014).

Figure 2

Source: (Appelrath & Ritter 2013)

The purchasing goals have been analyzed and it has been observed that the best cost analysis techniques for the purpose of the cost analysis the Toyota Motor Corporation is Activity Based costing system. Activity based costing system is the translation process of the indirect costs into the direct costs by tracking of the appropriate cost drivers associated with the indirect costs.

As Toyota involves large number of activities in different segments of the manufacturing process, the cost is driven by pool of activities. This particular mode of costing will help the company in evaluating batch level activities, unit-level activities, facility costs and product level expenses. The unit level expenses are most relevant with volume produce d in units. These costs are typically the supplies and materials. The product level activities are specific to particular parts of the cars. These costs are in line with various types of the engineering activities performed by the company.

Multiple Sourcing Criteria of Toyota Motor Corporation

This particular method of costing will prove to be helpful in formulation various types of pricing strategies, services and performance evaluation of the costing system of the company. The first instances of the cost are considered as the cost arising as a result of the functional categories and departmental activities of the various types of business process. The challenging part of this costing system lies in determining the cost drivers are associated with the cost drivers. The observed drivers are used to connect the activities to customers, cost objects and products. The use of ABC system in the Toyota motor corporation will ensure the disclosure of low-volume products which tend to be more expensive while computing them with the traditional system of costing (Pazarceviren & Ozsuer, 2015).

This form of costing system is the most effective form of costing system for identifying the planned activities before implementing it into the business process. The desired actions can be taken onto consideration for the explicit line of the managers based on the activity based costing system. Moreover the present Kaizen system of the costing of the various purchasing items are similar to the ABC costing system and thus the implementation of the change process will cost effective and considerably time consuming process for the company (Martin, 2016).

Figure 3: Comparison of the Kaizen system of costing and activity based costing

Source: (Song & Yi, 2015)

Conclusion

The extensive of the report stets the various factors that act as the rationale for selection of the suppliers at Toyota. The presence of Tier 1 and Tier 2 suppliers suggests that the most appropriate method of costing will be effective for multiple sourcing of the suppliers. In this way the company will able to improve the procurement process from multiple sources of the suppliers. The issues relating to the forges quality certificate given by many suppliers is another raising concern for the company which needs to looked after. The Karljic Purchasing Portfolio clearly shows the profit impact of the company based on the supply risk. The latter part of the report shows the implementation of the Internet communication technology for the improvement of the purchasing goals of the company has been clearly stated ion the report. The integration of the purchasing department with the SAP systems software shows the real time updating of the purchasing activities of the company. The final part of the report shows an overview of the present system of the costing based on the Kaizen Model and also gives recommendation for implementation activity based costing system. The report also shows a detailed comparison between the two costing systems.

Reference List

Appelrath, H. J., & Ritter, J. (2013). SAP R/3 implementation: methods and tools. Springer Science & Business Media.

Artzblog.com. (2016). Retrieved 16 June 2016

Hines, P. (2015). Toyota supplier system in Japan and the UK. Developments in Logistics and Supply Chain Management: Past, Present and Future, 113.

Information Technology for Toyota_Motor (TM). (2016). Wikinvest.com. Retrieved 16 June 2016,

Jahani, A., Azmi Murad, M. A., bin Sulaiman, M. N., & Selamat, M. H. (2015). An agent-based supplier selection framework. Strategic Outsourcing: An International Journal, 8(2/3), 180-205. doi:10.1108/SO-01-2015-0003

Klöckner, C. A., Nayum, A., & Mehmetoglu, M. (2013). Positive and negative spillover effects from electric car purchase to car use. Transportation Research Part D: Transport and Environment, 21, 32-38.

Knight, L., Tu, Y. H., & Preston, J. (2014). Integrating skills profiling and purchasing portfolio management: An opportunity for building purchasing capability. International Journal of Production Economics, 147, 271-283.

Martin, J. (2016). Activity-Based Costing and Japanese Cost Management. Maaw.info. Retrieved 16 June 2016,

Monczka, R., Handfield, R., Giunipero, L., & Patterson, J. (2015). Purchasing and supply chain management. Cengage Learning.

Monczka, R., Handfield, R., Giunipero, L., & Patterson, J. (2015). Purchasing and supply chain management. Cengage Learning.

Mori, M., MacDorman, K. F., & Kageki, N. (2012). The uncanny valley [from the field]. Robotics & Automation Magazine, IEEE, 19(2), 98-100.

Pazarceviren, S. Y., Akcin, O., & Ozsuer, U. (2015). A MODEL SUGGESTION FOR BUDGETING ACTIVITY COST REDUCTION UNDER ACTIVITY BASED KAIZEN BUDGETING APPROACH. European Scientific Journal.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2017). Impact Of ICT On Supply Chain Management: A Case Study Of Toyota Motor Corporation Essay.. Retrieved from https://myassignmenthelp.com/free-samples/report-about-the-purchasing-management.

"Impact Of ICT On Supply Chain Management: A Case Study Of Toyota Motor Corporation Essay.." My Assignment Help, 2017, https://myassignmenthelp.com/free-samples/report-about-the-purchasing-management.

My Assignment Help (2017) Impact Of ICT On Supply Chain Management: A Case Study Of Toyota Motor Corporation Essay. [Online]. Available from: https://myassignmenthelp.com/free-samples/report-about-the-purchasing-management

[Accessed 31 May 2025].

My Assignment Help. 'Impact Of ICT On Supply Chain Management: A Case Study Of Toyota Motor Corporation Essay.' (My Assignment Help, 2017) <https://myassignmenthelp.com/free-samples/report-about-the-purchasing-management> accessed 31 May 2025.

My Assignment Help. Impact Of ICT On Supply Chain Management: A Case Study Of Toyota Motor Corporation Essay. [Internet]. My Assignment Help. 2017 [cited 31 May 2025]. Available from: https://myassignmenthelp.com/free-samples/report-about-the-purchasing-management.